In the world of engineering, precision is paramount. But can you always rely on traditional hand calculations to deliver the most accurate results? Simulation is revolutionizing the design process, offering a powerful tool to validate theoretical concepts and optimize designs.

This blog post explores the advantages of using SOLIDWORKS simulation to analyze a tapered rod under tensile load. We’ll compare the results obtained through hand calculations with those achieved through simulation, highlighting the valuable insights that simulation can provide. Get ready to delve into the world of simulation and discover how it can elevate your design confidence!

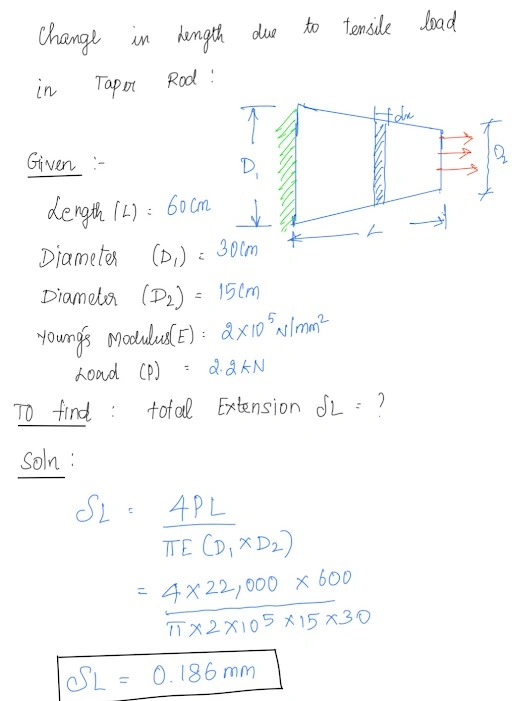

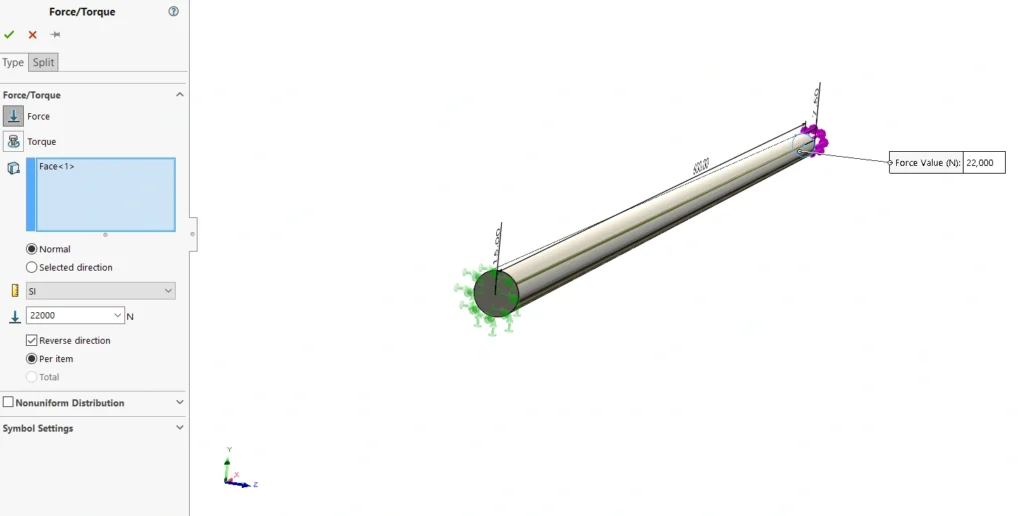

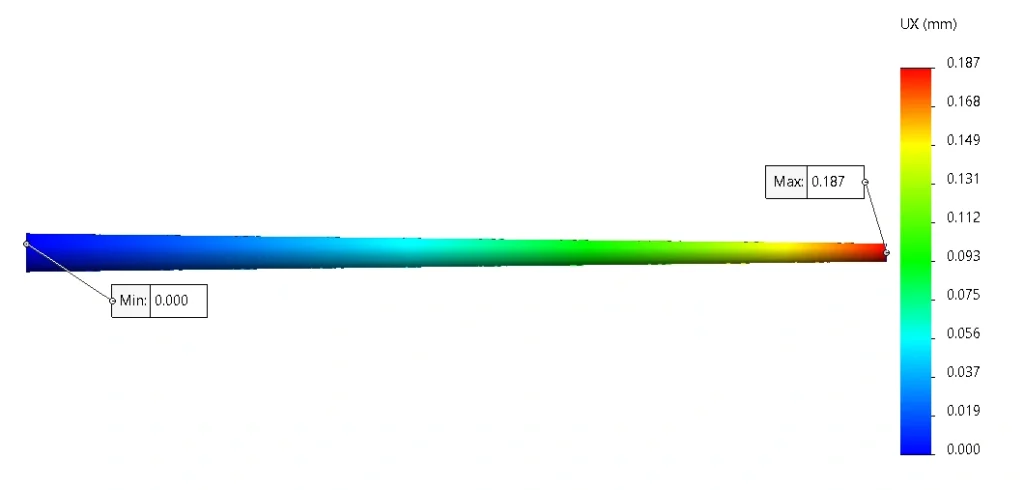

A steel rod circular in section, tapers from 3 cm diameter to 1.5 cm diameter in a length of 60 cm.Find how much its length will increase under a tensile force 22 kN. Take E = 2 x 105 N/ mm2

The Hand calculated taper Rod deflection is 0.186 mm. We will follow the solution using Simulation Package. The Material Properties introduced in the software.

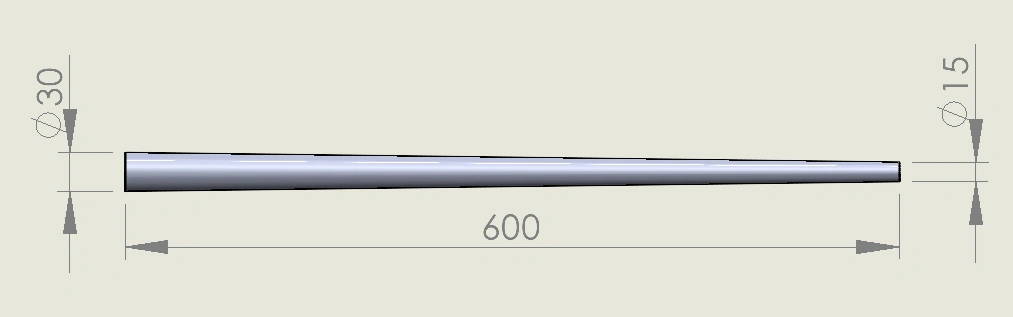

Create a Geometry to build in the software for given Dimensions:

Fig (1) 3D model of Taper Rod

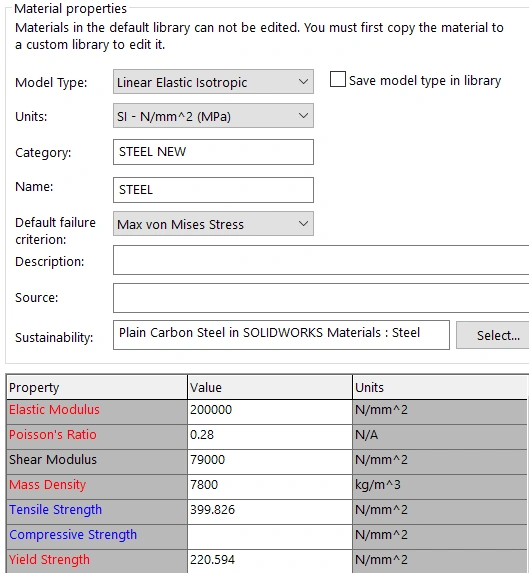

Fig (2) Material Properties involved in the calculation

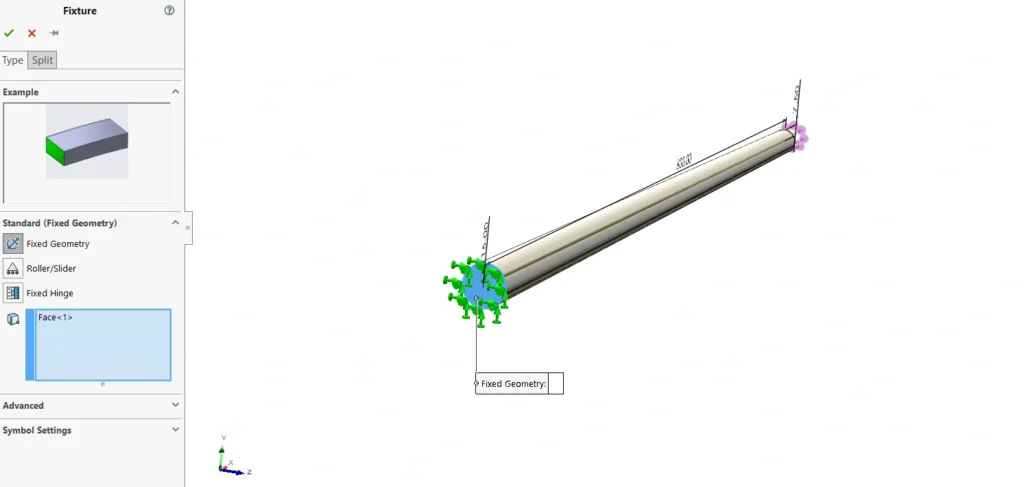

Boundary conditions involved as per theoretical conditions involved in the same.

Fig (3) Fixing at the larger end

For solid we can arrest the three Translation x, y, z and rotation of Three components will be eliminated.

Fig (4) Fixing at the smaller end

Tensile Load on the smaller end with the load of 22kN.

Conclusion for Enhancing Theoretical Calculation With Virtual Validation Using SOLIDWORKS Simulation:

We have compared the result of Taper rod subjected to tensile load using hand calculation and Solid works simulation. SolidWorks simulation is giving us most accurate result compared to theoretical value.

Thanks for any other excellent post. Where else may just anybody get that type of information in such an ideal way of writing? I have a presentation subsequent week, and I am at the look for such information.

Helpful information. Lucky me I found your site by chance, and I’m shocked why this accident didn’t came about earlier! I bookmarked it.

Can I just say what a relief to search out somebody who actually is aware of what theyre talking about on the internet. You definitely know methods to convey a difficulty to light and make it important. Extra people have to learn this and perceive this facet of the story. I cant believe youre not more widespread since you undoubtedly have the gift.

Woah! I’m really enjoying the template/theme of this blog. It’s simple, yet effective. A lot of times it’s challenging to get that “perfect balance” between superb usability and visual appeal. I must say that you’ve done a great job with this. Also, the blog loads very fast for me on Safari. Excellent Blog!

The very crux of your writing whilst appearing agreeable in the beginning, did not settle properly with me personally after some time. Somewhere throughout the sentences you actually were able to make me a believer unfortunately only for a short while. I however have a problem with your jumps in logic and you would do well to fill in those breaks. When you can accomplish that, I will definitely be impressed.

I know this if off topic but I’m looking into starting my own weblog and was curious what all is needed to get set up? I’m assuming having a blog like yours would cost a pretty penny? I’m not very web savvy so I’m not 100 certain. Any tips or advice would be greatly appreciated. Kudos

It is truly a nice and useful piece of info. I?¦m happy that you simply shared this useful information with us. Please keep us informed like this. Thank you for sharing.

Your article helped me a lot, is there any more related content? Thanks!

Thank you for sharing superb informations. Your web-site is very cool. I am impressed by the details that you have on this blog. It reveals how nicely you understand this subject. Bookmarked this website page, will come back for extra articles. You, my friend, ROCK! I found simply the information I already searched all over the place and simply could not come across. What an ideal site.

you may have an awesome blog right here! would you wish to make some invite posts on my weblog?

Great post, you have pointed out some fantastic details , I besides believe this s a very good website.

The subsequent time I read a blog, I hope that it doesnt disappoint me as much as this one. I imply, I know it was my choice to learn, but I really thought youd have something fascinating to say. All I hear is a bunch of whining about one thing that you could repair in the event you werent too busy searching for attention.

Excellent site. Plenty of useful info here. I am sending it to a few friends ans additionally sharing in delicious. And certainly, thank you for your sweat!

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

супрастин таблетки инструкция по применению взрослым от чего помогает https://allergiano.ru/ .

Would love to incessantly get updated outstanding web blog! .

obviously like your web site however you need to check the spelling on several of your posts. Several of them are rife with spelling issues and I to find it very bothersome to tell the truth then again I¦ll surely come again again.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Woah! I’m really digging the template/theme of this site. It’s simple, yet effective. A lot of times it’s very difficult to get that “perfect balance” between superb usability and appearance. I must say you’ve done a superb job with this. In addition, the blog loads super fast for me on Chrome. Excellent Blog!

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me? https://accounts.binance.com/ro/register?ref=V3MG69RO

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me? https://www.binance.com/hu/register?ref=FIHEGIZ8

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Very clear website , thanks for this post.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I have learn several just right stuff here. Certainly value bookmarking for revisiting. I surprise how much attempt you place to create this sort of great informative web site.

Enjoyed looking at this, very good stuff, regards.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

1win bet deposit [url=http://1win12.com.ng]http://1win12.com.ng[/url] .

1.вин [url=http://1win6001.ru]http://1win6001.ru[/url] .

1 win вход [url=https://1win6001.ru]https://1win6001.ru[/url] .

один вин официальный сайт [url=https://1win6020.ru/]один вин официальный сайт[/url] .

1win casino [url=http://1win12.com.ng/]http://1win12.com.ng/[/url] .

1вин сайт официальный [url=www.familyclub.borda.ru/?1-6-0-00002163-000-0-0-1743051813]1вин сайт официальный[/url] .

1 win pro [url=https://1win6020.ru]1 win pro[/url] .

скачать mostbet на телефон [url=mostbet6006.ru]скачать mostbet на телефон[/url] .

1 win.com [url=https://www.familyclub.borda.ru/?1-6-0-00002163-000-0-0-1743051813]https://www.familyclub.borda.ru/?1-6-0-00002163-000-0-0-1743051813[/url] .

продвижение сайтов москва продвижение сайтов москва .

mostbet [url=mostbet6006.ru]mostbet6006.ru[/url] .

раскрутка сайтов в москве раскрутка сайтов в москве .

1vin pro [url=www.alfatraders.borda.ru/?1-0-0-00004932-000-0-0-1743258210]1vin pro[/url] .

1вин официальный сайт [url=http://1win6049.ru/]http://1win6049.ru/[/url] .

1win играть [url=http://alfatraders.borda.ru/?1-0-0-00004932-000-0-0-1743258210]1win играть[/url] .

1win играть [url=http://1win6002.ru]http://1win6002.ru[/url] .

мостбет скачать бесплатно [url=https://www.mostbet6007.ru]https://www.mostbet6007.ru[/url] .

1 win казино [url=https://1win6002.ru]1 win казино[/url] .

mostbet casino [url=https://www.mostbet6007.ru]mostbet casino[/url] .

1 вин официальный [url=https://1win6049.ru/]https://1win6049.ru/[/url] .

1вин про [url=https://balashiha.myqip.ru/?1-12-0-00000437-000-0-0-1743258848/]https://balashiha.myqip.ru/?1-12-0-00000437-000-0-0-1743258848/[/url] .

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

1 win pro [url=www.balashiha.myqip.ru/?1-12-0-00000437-000-0-0-1743258848]www.balashiha.myqip.ru/?1-12-0-00000437-000-0-0-1743258848[/url] .

1 вин официальный сайт вход [url=www.1win6050.ru]1 вин официальный сайт вход[/url] .

1вин. [url=http://1win6050.ru]http://1win6050.ru[/url] .

1win казино [url=https://www.obovsem.myqip.ru/?1-9-0-00000059-000-0-0-1743051936]https://www.obovsem.myqip.ru/?1-9-0-00000059-000-0-0-1743051936[/url] .

1вин официальный сайт [url=1win6003.ru]1win6003.ru[/url] .

служба поддержки мостбет номер телефона [url=https://mostbet6008.ru/]служба поддержки мостбет номер телефона[/url] .

1вин [url=www.1win6003.ru]www.1win6003.ru[/url] .

скачат мостбет [url=mostbet6008.ru]скачат мостбет[/url] .

скачат мостбет [url=https://svstrazh.forum24.ru/?1-18-0-00000136-000-0-0-1743260517]https://svstrazh.forum24.ru/?1-18-0-00000136-000-0-0-1743260517[/url] .

1вин официальный мобильная [url=https://obovsem.myqip.ru/?1-9-0-00000059-000-0-0-1743051936]https://obovsem.myqip.ru/?1-9-0-00000059-000-0-0-1743051936[/url] .

мостбет официальный сайт [url=http://svstrazh.forum24.ru/?1-18-0-00000136-000-0-0-1743260517]http://svstrazh.forum24.ru/?1-18-0-00000136-000-0-0-1743260517[/url] .

рулонные шторы для панорамных окон рулонные шторы для панорамных окон .

Excellent web site. A lot of useful information here. I¦m sending it to some friends ans additionally sharing in delicious. And of course, thanks to your effort!

ролевые шторы ролевые шторы .

игра 1вин [url=http://1win6052.ru]http://1win6052.ru[/url] .

Профессиональный сервисный центр по ремонту бытовой техники с выездом на дом.

Мы предлагаем:ремонт крупногабаритной техники в москве

Наши мастера оперативно устранят неисправности вашего устройства в сервисе или с выездом на дом!

Где купить диплом по необходимой специальности?

Купить диплом университета по доступной стоимости возможно, обратившись к надежной специализированной компании.: diplom-insti.ru

Мы изготавливаем дипломы любой профессии по выгодным ценам. Дипломы изготавливаются на настоящих бланках государственного образца Купить диплом об образовании diplomv-v-ruki.ru

Your article helped me a lot, is there any more related content? Thanks!

Have you ever considered writing an e-book or guest authoring on other websites? I have a blog based upon on the same topics you discuss and would love to have you share some stories/information. I know my audience would enjoy your work. If you’re even remotely interested, feel free to shoot me an e mail.

1 вин вход [url=www.1win6052.ru]www.1win6052.ru[/url] .

mostbets [url=https://mostbet6009.ru/]mostbets[/url] .

бк 1win [url=https://www.1win6004.ru]https://www.1win6004.ru[/url] .

скачать мостбет [url=www.mostbet6009.ru]www.mostbet6009.ru[/url] .

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

1win партнерка вход [url=https://1win6004.ru]https://1win6004.ru[/url] .

1 win официальный [url=http://1win6051.ru]http://1win6051.ru[/url] .

аренда больших шатров московская область аренда больших шатров московская область .

Great beat ! I wish to apprentice at the same time as you amend your site, how can i subscribe for a blog site? The account helped me a applicable deal. I have been a little bit familiar of this your broadcast offered vibrant transparent idea

1 win регистрация [url=1win6051.ru]1 win регистрация[/url] .

тенты в москве аренда http://www.shatry-dlya-meropriyatiy.ru/ .

Мы изготавливаем дипломы психологов, юристов, экономистов и любых других профессий по приятным тарифам.– kupitediplom0027.ru/kupit-diplom-s-provodkoj-po-razumnoj-tsene/

Для удачного продвижения вверх по карьерной лестнице понадобится наличие диплома о высшем образовании. Купить диплом о высшем образовании у проверенной фирмы: diplomt-v-samare.ru/kupit-diplom-po-dostupnim-tsenam-v-omske/

Wonderful website. Plenty of helpful information here. I¦m sending it to several friends ans additionally sharing in delicious. And naturally, thank you on your sweat!

мосбет казино [url=mostbet6010.ru]mostbet6010.ru[/url] .

мотбет [url=mostbet6010.ru]mostbet6010.ru[/url] .

1 вин про [url=www.1win6053.ru]www.1win6053.ru[/url] .

1 win.pro [url=www.1win6053.ru]www.1win6053.ru[/url] .

portofele electronice casino [url=http://1win5004.ru]http://1win5004.ru[/url] .

1win pariuri [url=http://1win5004.ru]http://1win5004.ru[/url] .

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

1 вин официальный [url=www.1win6005.ru]www.1win6005.ru[/url] .

служба поддержки мостбет номер телефона https://www.mostbet6030.ru .

1win kg скачать [url=http://1win6005.ru]http://1win6005.ru[/url] .

скачать мостбет http://mostbet6030.ru .

1win.pro https://1win6054.ru/ .

1win sports betting https://1win13.com.ng/ .

1 win https://1win6054.ru/ .

1 win https://www.1win13.com.ng .

1win вход [url=http://1win6006.ru]http://1win6006.ru[/url] .

1win md [url=www.1win5011.ru]www.1win5011.ru[/url] .

1вин кг [url=www.1win6006.ru]1вин кг[/url] .

aplicația 1win [url=https://1win5011.ru]https://1win5011.ru[/url] .

win1 casino [url=https://1win1001.top]win1 casino[/url] .

1win зайти https://1win6042.ru/ .

casino en 1 win [url=http://1win1001.top]http://1win1001.top[/url] .

motbet mostbet6032.ru .

1 win.pro https://1win6042.ru .

скачать мостбет http://www.mostbet6031.ru .

мостбет казино войти https://mostbet6033.ru/ .

1win на телефон https://www.1win6043.ru .

поддержка мостбет http://mostbet6032.ru .

мостбет промокод мостбет промокод .

1вин http://www.1win6043.ru .

мост бет http://mostbet6033.ru/ .

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

1win nigeria [url=www.1win14.com.ng]1win nigeria[/url] .

1win букмекер [url=https://1win6009.ru]1win букмекер[/url] .

how to bet on 1win [url=https://1win14.com.ng]how to bet on 1win[/url] .

1win вход [url=https://1win6009.ru]1win вход[/url] .

1win.com [url=1win5012.ru]1win.com[/url] .

мостюет [url=www.mostbet6012.ru]www.mostbet6012.ru[/url] .

мостюет http://mostbet6011.ru .

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

1win.com [url=https://1win5012.ru/]https://1win5012.ru/[/url] .

aviator mostbet https://mostbet6011.ru/ .

адин вин https://1win6043.ru/ .

1wiun http://1win6043.ru/ .

скачать mostbet на телефон [url=www.mostbet6012.ru]www.mostbet6012.ru[/url] .

1win,com [url=http://1win6046.ru]http://1win6046.ru[/url] .

1 win официальный [url=https://www.1win6046.ru]1 win официальный[/url] .

1win личный кабинет [url=http://1win6047.ru]http://1win6047.ru[/url] .

сайт 1win официальный сайт вход [url=http://1win6047.ru/]сайт 1win официальный сайт вход[/url] .

Заказать диплом ВУЗа!

Заказать диплом института по невысокой стоимости возможно, обращаясь к проверенной специализированной фирме. Приобрести диплом: freediplom.com/diplom-s-reestrom-podlinnost-garantirovana

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

тревожная кнопка вневедомственная охрана тревожная кнопка вневедомственная охрана .

тревожная кнопка стоимость trevros.ru .

Мы можем предложить дипломы любых профессий по доступным тарифам.

Вы покупаете документ в надежной и проверенной временем компании. Заказать диплом университета– http://zxz.listbb.ru/viewtopic.phpf=7&t=10704/ – zxz.listbb.ru/viewtopic.phpf=7&t=10704

Для быстрого продвижения вверх по карьерной лестнице требуется наличие диплома ВУЗа. Быстро и просто купить диплом ВУЗа у сильной организации: diplomt-v-samare.ru/kupite-diplom-o-visshem-obrazovanii-v-omske/

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Приобрести диплом ВУЗа по выгодной стоимости можно, обращаясь к надежной специализированной компании. Купить документ о получении высшего образования вы имеете возможность у нас в столице. diplom-kaluga.ru/kupit-diplom-s-zaneseniem-v-reestr-po-vigodnoj-tsene-21

Приобрести диплом о высшем образовании!

Наши специалисты предлагаютбыстро и выгодно приобрести диплом, который выполняется на оригинальном бланке и заверен мокрыми печатями, водяными знаками, подписями должностных лиц. Данный документ способен пройти любые проверки, даже с использованием специально предназначенного оборудования. Достигайте своих целей быстро и просто с нашим сервисом- radiocoop.co/2025/04/14/kupit-diplom-prostoe-reshenie-dlja-slozhnyh-zadach-11

Мы предлагаем дипломы любой профессии по доступным тарифам. Стараемся поддерживать для покупателей адекватную ценовую политику. Важно, чтобы документы были доступны для большинства наших граждан.

Заказ документа, подтверждающего обучение в университете, – это выгодное решение. Купить диплом о высшем образовании: kupite-diplom0024.ru/diplom-rf-kupit/

Приобрести диплом ВУЗа по выгодной цене можно, обращаясь к надежной специализированной компании. Заказать документ института можно в нашем сервисе. diplom-ryssia.com/kupit-diplom-visshego-obrazovaniya-s-zaneseniem-v-reestr-29

аттестат 2010 купить аттестат 2010 купить .

Приобрести диплом о высшем образовании!

Мы предлагаемвыгодно и быстро приобрести диплом, который выполняется на бланке ГОЗНАКа и заверен мокрыми печатями, штампами, подписями. Документ пройдет лубую проверку, даже при помощи специфических приборов. Достигайте цели быстро с нашими дипломами- mosros.flybb.ru/viewtopic.phpf=2&t=834

Мы изготавливаем дипломы любых профессий по приятным ценам. Стараемся поддерживать для заказчиков адекватную политику тарифов. Важно, чтобы дипломы были доступными для подавляющей массы граждан.

Покупка диплома, подтверждающего окончание ВУЗа, – это грамотное решение. Приобрести диплом любого ВУЗа: 1magistr.ru/kupit-diplom-o-obrazovanii-2/

купить книжку диплома rusdiplomm-orig.ru .

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

мотбет [url=https://www.mostbet7005.ru]https://www.mostbet7005.ru[/url] .

мостбет войти [url=http://mostbet7005.ru]мостбет войти[/url] .

Где заказать диплом специалиста?

Приобрести диплом института по невысокой цене вы сможете, обращаясь к надежной специализированной фирме.: prodiplome.com

Мы можем предложить дипломы любых профессий по выгодным тарифам. Дипломы производят на настоящих бланках Заказать диплом университета diplomt-v-chelyabinske.ru

Эксклюзивные римские шторы по вашим размерам

римские шторы на заказ римские шторы на заказ .

Закажите уникальные шторы на заказ, для вашего дома.

Качественные шторы на заказ, по выгодной цене.

Изготовление штор на заказ, по вашим размерам.

Шторы на заказ с доставкой, высокое качество материалов.

Заказать шторы на заказ для спальни, под ваш вкус.

Надежное изготовление штор на заказ, по вашим желанием.

Пошив штор для нестандартных окон, по желанию.

Шторы на заказ с уникальным дизайном, от профессионалов.

Классические шторы на заказ, под любой интерьер.

Шторы на заказ с учетом ваших пожеланий, по вашему стилю.

Изготовление штор на заказ на любой вкус, под любой интерьер.

Пошив штор по индивидуальному проекту, по вашему желанию.

Модные шторы на заказ для вашего дома, под ваш бюджет.

Индивидуальный пошив штор на заказ, по вашему проекту.

Пошив штор по индивидуальному дизайну, от профессиональных мастеров.

Эксклюзивные ткани для пошива штор, с гарантией долговечности.

сшить шторы на заказ сшить шторы на заказ . прокарниз

мос бет [url=mostbet6013.ru]мос бет[/url] .

mostbet игры [url=https://mostbet6013.ru/]https://mostbet6013.ru/[/url] .

Приобрести диплом о высшем образовании !

Приобретение диплома университета РФ в нашей компании – надежный процесс, ведь документ будет заноситься в государственный реестр. Купить диплом о высшем образовании diplomservis.ru/poluchite-diplom-s-zaneseniem-v-reestr-bistro-i-legko-2

Всегда считал, что покупка диплома о высшем образовании — это миф и невозможно. Но, к счастью, оказался неправ. Сначала искал информацию по теме: купить диплом дефектолога, купить диплом инженера механика, куплю диплом самой, купить диплом начальных классов, купить диплом образования во владивостоке, а затем переключился на дипломы вузов. Подробности здесь: diplomybox.com/kupit-diplom-bakalavra-v-ulyanovske

olympe casino https://olympecasino.pro/# olympe

olympe casino cresus

Премиум пошив штор

пошив штор на заказ пошив штор на заказ .

Дизайн штор в загородном доме

шторы в загородном доме шторы в загородном доме .+7 (499) 460-69-87

Absolutely written subject material, Really enjoyed studying.

Лучшие шторы на заказ — качество и стиль

шторы на заказ шторы на заказ . +7 (499) 460-69-87

Купить диплом университета по доступной стоимости вы сможете, обратившись к надежной специализированной компании. Мы оказываем услуги по продаже документов об окончании любых ВУЗов РФ. Купить диплом университета– diplomskiy.com/kupit-diplom-s-zaneseniem-v-reestr-bistro-i-nadezhno-68/

Acheter Kamagra site fiable: Achetez vos kamagra medicaments – kamagra oral jelly

Роскошные шторы на заказ для изысканных интерьеров

шторы на заказ шторы на заказ . Ткацкий

Лучшие шторы для спокойствия и уюта, создайте уют, подбираем шторы для загородного дома, стильный дизайн штор, стиль и удобство, современные материалы для штор, шторы для защиты от солнца, стильные решения для штор, выбираем шторы для загородной гостиной, примеры оформления окон с шторами, шторы из натуральных тканей, современные механизмы для штор, стили штор для различных комнат, шторы как часть интерьера, сделайте выбор в пользу уютных штор, лучшие идеи для оформления окон, сравнение видов штор для дачи, создайте уют с помощью уникальных штор, идеи сезонного оформления окон

шторы в загородном доме шторы в загородном доме .

Лучшие решения для штор на заказ

сшить шторы на заказ сшить шторы на заказ . Ткацкий

Умные деревянные жалюзи с электроприводом

Деревянные горизонтальные жалюзи с электроприводом Деревянные горизонтальные жалюзи с электроприводом . +7 (499) 638-25-37

Качественные шторы, сделанные на заказ

сшить шторы на заказ сшить шторы на заказ . Ткацкий

Индивидуальный пошив штор, эксклюзивный пошив штор..

Идеальные шторы на заказ, с гарантией качества..

Пошив штор на заказ, по индивидуальному проекту..

Пошив штор по вашему дизайну, обратитесь к нам..

Быстрый пошив штор, по вашим требованиям..

Мастерская по пошиву штор, гарантия качества..

Дизайнерские шторы на любой интерьер, Позвольте нам помочь..

Премиальный пошив штор, от ведущих мастеров..

Изысканный пошив штор, для элитных интерьеров..

Экспертный пошив штор в кратчайшие сроки, оформляйте заказ онлайн..

Пошив штор высокого качества, по вашему дизайну..

Разнообразие тканей и стилей, подходящий ваш стиль..

Пошив штор с профессиональным монтажом, от профессионалов..

Уникальные шторы с пошивом на заказ, по вашим требованиям..

Пошив штор для любого помещения, подчеркивающих ваш стиль..

Профессиональный пошив штор, по вашему стилю..

Создаем шторы, которые преобразят ваш интерьер, по оптимальной цене..

пошив штор пошив штор . Ткацкий

Как выбрать шторы для коттеджа

шторы для коттеджа шторы для коттеджа .

kamagra gel: kamagra en ligne – kamagra livraison 24h

Лучшие шторы для коттеджа

шторы для коттеджа шторы для коттеджа .

Kamagra Oral Jelly pas cher: kamagra livraison 24h – kamagra pas cher

Создайте уют с автоматикой Somfy

Автоматика Somfy Автоматика Somfy . Прокарниз

pharmacie en ligne france fiable: Pharmacie en ligne France – п»їpharmacie en ligne france pharmafst.com

pharmacie en ligne france livraison belgique: pharmacie en ligne pas cher – pharmacie en ligne fiable pharmafst.com

Автоматика Somfy — комфорт и безопасность

Автоматика Somfy Автоматика Somfy . прокарниз

Идеи для штор в загородном доме, выберите стиль, лучшие материалы для штор в загородных домах, стильный дизайн штор, максимальная функциональность, экологичные шторы для дома, шторы для защиты от солнца, стильные решения для штор, выбираем шторы для загородной гостиной, примеры оформления окон с шторами, шторы из натуральных тканей, современные механизмы для штор, гармония штор и мебели, украшение окон штором, сделайте выбор в пользу уютных штор, выбор стильных штор для загородного дома, что выбрать для загородного дома, подчеркните архитектуру дома с помощью штор, подбираем шторы под сезон

шторы в загородном доме шторы в загородном доме .

Kamagra Oral Jelly pas cher: Kamagra Commander maintenant – kamagra oral jelly

Tadalafil 20 mg prix sans ordonnance: Tadalafil 20 mg prix sans ordonnance – Acheter Cialis 20 mg pas cher tadalmed.shop

pharmacie en ligne pas cher: Medicaments en ligne livres en 24h – pharmacie en ligne sans ordonnance pharmafst.com

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Качественные жалюзи с пультом по выгодной цене

жалюзи с пультом жалюзи с пультом . прокарниз

Cialis sans ordonnance 24h: cialis generique – Tadalafil achat en ligne tadalmed.shop

acheter kamagra site fiable: Kamagra Commander maintenant – kamagra livraison 24h

Умные жалюзи с пультом — современное решение для вашего окна

жалюзи с пультом жалюзи с пультом . прокарниз

Деревянные жалюзи с электроприводом: современные технологии

Деревянные горизонтальные жалюзи с электроприводом Деревянные горизонтальные жалюзи с электроприводом . +7 (499) 638-25-37

kamagra livraison 24h: acheter kamagra site fiable – achat kamagra

kamagra gel: kamagra gel – Acheter Kamagra site fiable

Cialis en ligne: Tadalafil sans ordonnance en ligne – Acheter Cialis tadalmed.shop

Tadalafil 20 mg prix en pharmacie: Cialis sans ordonnance 24h – Tadalafil 20 mg prix sans ordonnance tadalmed.shop

kamagra livraison 24h: Achetez vos kamagra medicaments – kamagra gel

Электропривод для жалюзи: современные технологии

электропривод для горизонтальных жалюзи электропривод для горизонтальных жалюзи .

pharmacie en ligne france fiable: pharmacie en ligne pas cher – acheter mГ©dicament en ligne sans ordonnance pharmafst.com

Электропривод для горизонтальных жалюзи купить в Москве

электропривод для горизонтальных жалюзи электропривод для горизонтальных жалюзи .

Tadalafil 20 mg prix sans ordonnance: Tadalafil sans ordonnance en ligne – cialis generique tadalmed.shop

Kamagra Commander maintenant: Kamagra pharmacie en ligne – acheter kamagra site fiable

Современные моторизированные жалюзи — удобно и красиво

моторизированные жалюзи моторизированные жалюзи . Прокарниз

kamagra gel: kamagra en ligne – Kamagra pharmacie en ligne

cialis generique: Cialis en ligne – Cialis sans ordonnance 24h tadalmed.shop

Современные моторизированные жалюзи — удобно и красиво

моторизированные жалюзи моторизированные жалюзи . Prokarniz

pharmacie en ligne: pharmacie en ligne livraison europe – pharmacie en ligne france fiable pharmafst.com

Электроприводные деревянные жалюзи: комфорт и стиль

Деревянные горизонтальные жалюзи с электроприводом Деревянные горизонтальные жалюзи с электроприводом . Prokarniz

cialis generique: Cialis sans ordonnance 24h – Cialis generique prix tadalmed.shop

vente de mГ©dicament en ligne: pharmacie en ligne pas cher – pharmacie en ligne france livraison internationale pharmafst.com

Элегантные деревянные жалюзи с электроприводом

Деревянные горизонтальные жалюзи с электроприводом Деревянные горизонтальные жалюзи с электроприводом . Прокарниз

Kamagra Oral Jelly pas cher: kamagra 100mg prix – kamagra gel

Идеи для штор в загородном доме, подчеркните дизайн, подбираем шторы для загородного дома, эстетика и комфорт, продуманный дизайн, современные материалы для штор, шторы для приватности, стильные решения для штор, выбираем шторы для загородной гостиной, примеры оформления окон с шторами, стильные шторы из льна и холста, современные механизмы для штор, гармония штор и мебели, декор и оформление окон в загородном доме, обеспечьте комфорт с нашими шторами, тренды в шторном дизайне 2025, сравнение видов штор для дачи, создайте уют с помощью уникальных штор, подбираем шторы под сезон

шторы в загородном доме шторы в загородном доме .

indian pharmacy: Medicine From India – MedicineFromIndia

Выгодно купить диплом любого университета!

Мы оказываем услуги по производству и продаже документов об окончании любых университетов РФ. Документы изготавливаются на фирменных бланках государственного образца. kherson.forum2x2.ru/login

indian pharmacy online: medicine courier from India to USA – Medicine From India

Лучшие шторы для спокойствия и уюта, при помощи красивых штор, лучшие материалы для штор в загородных домах, эстетика и комфорт, продуманный дизайн, современные материалы для штор, шторы для приватности, идеи дизайна штор, выбираем шторы для загородной гостиной, шторные решения для больших окон, стильные шторы из льна и холста, современные механизмы для штор, стили штор для различных комнат, украшение окон штором, сделайте выбор в пользу уютных штор, выбор стильных штор для загородного дома, сравнение видов штор для дачи, создайте уют с помощью уникальных штор, шторы для зимнего уюта в загородном доме

шторы в загородном доме шторы в загородном доме .

Где заказать диплом по нужной специальности?

Полученный диплом с приложением полностью отвечает стандартам, никто не сможет отличить его от оригинала. Не откладывайте свои мечты на потом, реализуйте их с нашей помощью – отправьте заявку на изготовление документа сегодня! Диплом о высшем образовании – легко! lotusprotechnologies.com/companies/premialnie-diplom-24

precription drugs from canada: Express Rx Canada – legitimate canadian pharmacy

Пошив штор на любой вкус, профессиональный пошив штор..

Пошив штор для вашего дома, по доступным ценам..

Эксклюзивные решения в пошиве штор, с использованием лучших тканей..

Пошив штор по вашему дизайну, звоните сейчас..

Быстрый пошив штор, под ключ..

Пошив штор премиум-класса, по выгодным ценам..

Дизайнерские шторы на любой интерьер, Позвольте нам помочь..

Премиальный пошив штор, вам под силу..

Пошив штор из эксклюзивных тканей, по индивидуальному проекту..

Пошив штор с индивидуальным подходом, получите консультацию..

Пошив штор высокого качества, по лучшим ценам..

Разнообразие тканей и стилей, подходящий ваш стиль..

Элегантные шторы на заказ, под ключ..

Уникальные шторы с пошивом на заказ, с индивидуальным подходом..

Пошив штор для любого помещения, подчеркивающих ваш стиль..

Профессиональный пошив штор, по вашему стилю..

Пошив штор по вашим пожеланиям, от замеров до монтажа..

пошив штор пошив штор . “Ткацкий”

canadian pharmacy online ship to usa: Generic drugs from Canada – buying drugs from canada

canadian pharmacy online store: Buy medicine from Canada – medication canadian pharmacy

Индивидуальный пошив штор, эксклюзивный пошив штор..

Пошив штор для вашего дома, с гарантией качества..

Индивидуальный пошив штор под любую комнату, с использованием лучших тканей..

Дизайнерские шторы на заказ, обратитесь к нам..

Пошив штор с доставкой, по вашим требованиям..

Лучшие ткани для пошива штор, по индивидуальному заказу..

Создаем шторы мечты, Позвольте нам помочь..

Премиальный пошив штор, по вашему стилю..

Эксклюзивные шторы на заказ, по вашим желанием..

Пошив штор с индивидуальным подходом, оформляйте заказ онлайн..

Мастера по пошиву штор, по лучшим ценам..

Премиум пошив штор для интерьера, с бесплатной доставкой..

Индивидуальный стиль ваших окон, от профессионалов..

Уникальные шторы с пошивом на заказ, по вашим требованиям..

Пошив штор для любого помещения, подчеркивающих ваш стиль..

Лучшие ткани для пошива штор, с гарантией долговечности..

Пошив штор по вашим пожеланиям, с бесплатной консультацией..

пошив штор пошив штор . “Ткацкий”

best canadian pharmacy Generic drugs from Canada best canadian online pharmacy

medicine courier from India to USA: Medicine From India – indian pharmacy

canadian compounding pharmacy: Express Rx Canada – canada discount pharmacy

Практичные шторы для загородных интерьеров

шторы в загородном доме шторы в загородном доме .+7 (499) 460-69-87

mexican rx online: Rx Express Mexico – Rx Express Mexico

best canadian online pharmacy Buy medicine from Canada canadianpharmacyworld

mexico pharmacies prescription drugs: mexican online pharmacy – Rx Express Mexico

Стильные решения штор для загородных коттеджей

шторы в загородном доме шторы в загородном доме .Ткацкий

Rx Express Mexico: mexico pharmacy order online – purple pharmacy mexico price list

indian pharmacy online shopping MedicineFromIndia MedicineFromIndia

canadian pharmacy in canada: Generic drugs from Canada – thecanadianpharmacy

Сшить шторы на заказ по индивидуальному проекту, для вашего дома.

Качественные шторы на заказ, быстро.

Создание штор мечты, под любой стиль.

Эксклюзивные шторы на заказ, подчеркивающие ваш стиль.

Пошив штор на заказ для кухни, под ваш вкус.

Профессиональный пошив штор по вашим размерам, быстро и качественно.

Заказ штор по проекту клиента, с учетом особенностей помещения.

Эксклюзивные шторы на заказ, подчеркивающие вашу индивидуальность.

Современные шторы на заказ, с учетом светотени.

Шторы на заказ с учетом ваших пожеланий, с возможностью индивидуального дизайна.

Премиальные ткани для штор на заказ, под любой интерьер.

Доступные цены на шторы на заказ, с доставкой по Москве и регионам.

Элегантные шторы на заказ, под ваш бюджет.

Дизайнерские шторы на заказ, по вашему проекту.

Создание уникальных штор для любой комнаты, под ваш вкус.

Пошив штор на заказ с индивидуальным подходом, по желанию клиента.

сшить шторы на заказ сшить шторы на заказ . прокарниз

Премиальные шторы на заказ для вашего интерьера, индивидуальный подход.

Премиальные шторы на заказ, быстро.

Пошив штор по индивидуальному дизайну, под любой стиль.

Шторы на заказ с доставкой, по индивидуальному дизайну.

Заказать шторы на заказ для спальни, с учетом модных трендов.

Профессиональный пошив штор по вашим размерам, быстро и качественно.

Заказ штор по проекту клиента, по желанию.

Эксклюзивные шторы на заказ, от профессионалов.

Минималистичные шторы на заказ, по вашему проекту.

Создание штор для любого типа окна, по вашему стилю.

Премиальные ткани для штор на заказ, воплощая ваши идеи.

Пошив штор по индивидуальному проекту, с доставкой по Москве и регионам.

Стильные шторы по вашему проекту, от ведущих дизайнеров.

Дизайнерские шторы на заказ, подчеркните стиль вашего помещения.

Пошив штор по индивидуальному дизайну, от профессиональных мастеров.

Пошив штор на заказ с индивидуальным подходом, по желанию клиента.

сшить шторы на заказ сшить шторы на заказ . прокарниз

Облегчите жизнь с жалюзи с пультом — современно и удобно

жалюзи с пультом жалюзи с пультом . +7 (499) 638-25-37

pinup az: pin up azerbaycan – pin-up casino giris

Элегантные жалюзи с пультом для вашего дизайнерского решения

жалюзи с пультом жалюзи с пультом . прокарниз

vavada: vavada вход – вавада казино

склад под хранение вещей аренда [url=https://hranimveshimsk.ru/]склад под хранение вещей аренда[/url] .

Превратите дом в умную технику с Somfy

Автоматика Somfy Автоматика Somfy . прокарниз

pin-up casino giris: pin up az – pinup az

Превратите дом в умную технику с Somfy

Автоматика Somfy Автоматика Somfy . Prokarniz

пин ап казино: пин ап вход – pin up вход

место хранения вещей в москве [url=https://hranimveshimsk.ru/]место хранения вещей в москве[/url] .

аккаунт для рекламы перепродажа аккаунтов

маркетплейс аккаунтов купить аккаунт с прокачкой

пин ап зеркало: пинап казино – пинап казино

Шторы для коттеджа: идеи и выбор

шторы для коттеджа шторы для коттеджа .

продать аккаунт маркетплейс для реселлеров

вавада: вавада официальный сайт – vavada casino

маркетплейс аккаунтов соцсетей магазин аккаунтов социальных сетей

Гармония интерьера с помощью штор в коттедже

шторы для коттеджа шторы для коттеджа .

продажа аккаунтов соцсетей купить аккаунт

vavada: vavada casino – vavada

гарантия при продаже аккаунтов https://kupit-akkaunt-top.ru/

магазин аккаунтов маркетплейс аккаунтов

Шторы на заказ с индивидуальным дизайном

сшить шторы на заказ сшить шторы на заказ . +7 (499) 460-69-87

пин ап вход: пин ап зеркало – pin up вход

Шторы на заказ: стиль и качество

сшить шторы на заказ сшить шторы на заказ . “Ткацкий”

пин ап вход: пин ап зеркало – пинап казино

Шторы на заказ — индивидуальный подход к вашему интерьеру

шторы на заказ шторы на заказ . Ткацкий

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Online Account Store Account Catalog

Account Trading Platform Account marketplace

Шторы на заказ — решение для вашей квартиры и дома

шторы на заказ шторы на заказ . +7 (499) 460-69-87

Account Store Buy accounts

пин ап вход: пин ап вход – пин ап зеркало

Online Account Store Account market

Римские шторы на заказ — комфорт и стиль

римские шторы на заказ римские шторы на заказ .

vavada вход: vavada вход – вавада официальный сайт

Римские шторы по индивидуальному проекту

римские шторы на заказ римские шторы на заказ .

vavada вход: vavada – вавада официальный сайт

Social media account marketplace Social media account marketplace

Marketplace for Ready-Made Accounts Accounts market

Ручной пошив штор

пошив штор на заказ пошив штор на заказ .

Website for Buying Accounts Accounts for Sale

vavada casino: вавада казино – вавада казино

Уникальные шторы под заказ

пошив штор на заказ пошив штор на заказ .

вавада: вавада – vavada casino

продамус промокоды [url=prodams-promokod.ru]продамус промокоды[/url] .

Account Buying Service Gaming account marketplace

Account Exchange Service Account Trading Service

pin up вход: пин ап зеркало – pin up вход

Secure Account Sales Account Sale

пинап казино: пин ап вход – пин ап казино официальный сайт

vavada: vavada casino – вавада зеркало

accounts market account catalog

secure account sales gaming account marketplace

промокод prodamus [url=www.prodams-promokod.ru/]www.prodams-promokod.ru/[/url] .

account buying service secure account sales

вавада зеркало: вавада зеркало – вавада

ready-made accounts for sale profitable account sales

vavada: вавада зеркало – вавада

pin up azerbaycan: pin-up – pin up casino

account acquisition secure account purchasing platform

find accounts for sale profitable account sales

vavada вход: vavada casino – вавада зеркало

database of accounts for sale profitable account sales

Мы предлагаем дипломы любых профессий по приятным тарифам.– comedyforme.ru/kak-ne-oshibitsya-pri-vyibore-diploma

pin up casino: pin-up – pin up az

account acquisition secure account purchasing platform

gaming account marketplace database of accounts for sale

social media account marketplace sell accounts

account exchange service buy and sell accounts

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

accounts for sale database of accounts for sale

website for buying accounts secure account sales

accounts marketplace website for buying accounts

secure account purchasing platform account purchase

Мы изготавливаем дипломы психологов, юристов, экономистов и прочих профессий по выгодным тарифам.– arezonrp.forumex.ru/viewtopic.phpf=13&t=1331

Just here to dive into discussions, share thoughts, and gain fresh perspectives as I go.

I like learning from different perspectives and contributing whenever I can. Always open to different experiences and connecting with others.

There’s my website:https://automisto24.com.ua/

vavada вход: vavada casino – vavada

account catalog website for buying accounts

account catalog account marketplace

пин ап казино официальный сайт: pin up вход – пин ап казино официальный сайт

Happy to dive into discussions, exchange ideas, and gain fresh perspectives along the way.

I’m interested in understanding different opinions and adding to the conversation when possible. Happy to hear new ideas and building connections.

There’s my website:https://automisto24.com.ua/

account purchase account catalog

secure account purchasing platform https://buy-social-accounts.org/

accounts for sale accounts market

pin up: pin up azerbaycan – pin up casino

pin up вход: пин ап зеркало – пин ап казино

guaranteed accounts account store

account market guaranteed accounts

social media account marketplace verified accounts for sale

database of accounts for sale account purchase

услуги таможенного брокера услуги таможенного брокера .

таможенные брокеры таможенные брокеры .

account trading service account buying service

таможенный брокер шереметьево таможенный брокер шереметьево .

рулонные шторы на электроприводе рулонные шторы на электроприводе .

брокер на таможне брокер на таможне .

электрические рулонные шторы электрические рулонные шторы .

accounts market accounts for sale

account marketplace sell pre-made account

buy generic Viagra online: buy generic Viagra online – secure checkout Viagra

I got what you intend,saved to my bookmarks, very decent web site.

account exchange service https://accounts-offer.org

purchase ready-made accounts https://accounts-marketplace.xyz/

order Cialis online no prescription: generic tadalafil – cheap Cialis online

buy generic Viagra online: safe online pharmacy – legit Viagra online

website for selling accounts https://social-accounts-marketplaces.live

Modafinil for sale: safe modafinil purchase – modafinil pharmacy

website for buying accounts https://accounts-marketplace.live/

profitable account sales https://social-accounts-marketplace.xyz/

sell accounts https://buy-accounts.space

purchase Modafinil without prescription: safe modafinil purchase – purchase Modafinil without prescription

discreet shipping: generic sildenafil 100mg – Viagra without prescription

account trading platform https://buy-accounts-shop.pro/

cheap Cialis online: buy generic Cialis online – best price Cialis tablets

account market https://buy-accounts.live/

account purchase accounts marketplace

purchase Modafinil without prescription: doctor-reviewed advice – doctor-reviewed advice

guaranteed accounts https://social-accounts-marketplace.live

http://modafinilmd.store/# buy modafinil online

продамус промокоды [url=promokod-prod.ru]продамус промокоды[/url] .

reliable online pharmacy Cialis: discreet shipping ED pills – discreet shipping ED pills

Cialis without prescription: best price Cialis tablets – reliable online pharmacy Cialis

http://modafinilmd.store/# purchase Modafinil without prescription

secure checkout ED drugs: online Cialis pharmacy – online Cialis pharmacy

buy modafinil online: buy modafinil online – purchase Modafinil without prescription

This is really interesting, You are a very skilled blogger. I have joined your rss feed and look forward to seeking more of your excellent post. Also, I’ve shared your site in my social networks!

buy generic Cialis online: online Cialis pharmacy – secure checkout ED drugs

https://maxviagramd.com/# trusted Viagra suppliers

order Cialis online no prescription: reliable online pharmacy Cialis – cheap Cialis online

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

http://zipgenericmd.com/# Cialis without prescription

промокод продамус [url=http://promokod-prodam.ru]промокод продамус[/url] .

FDA approved generic Cialis: discreet shipping ED pills – cheap Cialis online

маркетплейс аккаунтов соцсетей маркетплейсов аккаунтов

маркетплейс аккаунтов соцсетей https://rynok-akkauntov.top

купить аккаунт https://kupit-akkaunt.xyz/

cost of generic clomid without dr prescription: where to get clomid without rx – how to get cheap clomid prices

amoxicillin 500mg price: Amo Health Care – amoxicillin 500mg cost

купить аккаунт https://akkaunt-magazin.online/

Amo Health Care: Amo Health Care – where to buy amoxicillin pharmacy

маркетплейс аккаунтов akkaunty-market.live

продать аккаунт https://kupit-akkaunty-market.xyz

amoxil pharmacy: amoxicillin 500mg cost – can i buy amoxicillin online

I have not checked in here for a while because I thought it was getting boring, but the last few posts are good quality so I guess I’ll add you back to my daily bloglist. You deserve it my friend 🙂

Модные жалюзи с пультом — подчеркните стиль вашего интерьера

жалюзи с пультом жалюзи с пультом . Prokarniz

Энергосберегающие жалюзи с пультом — экономия и комфорт

жалюзи с пультом жалюзи с пультом . Prokarniz

маркетплейс аккаунтов маркетплейсов аккаунтов

магазин аккаунтов https://online-akkaunty-magazin.xyz

шкафы в паркинг в москве шкафы в паркинг в москве .

маркетплейс аккаунтов https://akkaunty-dlya-prodazhi.pro/

Энергосбережение и удобство с Somfy

Автоматика Somfy Автоматика Somfy . прокарниз

роллетные шкафы в паркинг москва роллетные шкафы в паркинг москва .

маркетплейс аккаунтов соцсетей https://kupit-akkaunt.online

криптовалюта что это простыми [url=http://cryptohamsters.ru]http://cryptohamsters.ru[/url] .

как зарабатывать на криптовалюте [url=cryptohamsters.ru]как зарабатывать на криптовалюте[/url] .

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

buy facebook ads account https://buy-adsaccounts.work/

facebook ads account for sale https://buy-ad-accounts.click

buying facebook account buy facebook accounts for advertising

скачать песню бесплатно уннв http://25kat.ru/music/уннв/ .

уннв скачать музыку уннв скачать музыку .

buy facebook old accounts https://buy-ads-account.click

buy facebook old accounts buy facebook accounts

facebook accounts for sale https://buy-ads-account.work

fb accounts for sale https://ad-account-for-sale.top

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://accounts.binance.com/sl/register?ref=OMM3XK51

cialis indications: cialis and nitrates – canadian cialis 5mg

buy facebook ad account https://buy-ad-account.click

cialis effectiveness: cialis doesnt work – great white peptides tadalafil

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

facebook ad accounts for sale https://ad-accounts-for-sale.work

google ads account for sale https://buy-ads-account.top

buy cialis no prescription overnight: reliable source cialis – what is cialis tadalafil used for

google ads agency accounts buy google agency account

buy facebook accounts cheap buy facebook ads accounts

buy aged google ads account https://ads-account-for-sale.top

buy verified google ads accounts buy google ads

sell google ads account https://buy-ads-invoice-account.top/

sell google ads account https://buy-account-ads.work

google ads accounts for sale buy google adwords account

buy google adwords account https://sell-ads-account.click

buy google ads invoice account https://ads-agency-account-buy.click/

facebook bm account buy-business-manager.org

buy google ads verified account buy google adwords account

Приобрести диплом о высшем образовании. Производство документа занимает минимум времени, а стоимость при этом доступна каждому человеку. В итоге вы сможете сохранить бюджет и получить прекрасную работу мечты. Заказать диплом под заказ возможно используя сайт компании. – abroad.ekafe.ru/viewtopic.php?f=5&t=4412

facebook business account for sale https://buy-bm-account.org

buy facebook bm account buy facebook business manager

verified business manager for sale https://buy-verified-business-manager.org

окна рехау москва [url=02stroika.ru]окна рехау москва[/url] .

buy facebook bm buy-business-manager-acc.org

Заказать диплом института!

Приобретение официального диплома через надежную фирму дарит множество плюсов. Купить диплом института у сильной фирмы: doks-v-gorode-ulyanovsk-73.ru

buy facebook business account business-manager-for-sale.org

buy verified bm https://buy-business-manager-verified.org/

Профессиональный сервисный центр по ремонту техники в Уфе.

Мы предлагаем: Ремонт морозильных камер Delvento

Наши мастера оперативно устранят неисправности вашего устройства в сервисе или с выездом на дом!

buy facebook business manager accounts https://buy-bm.org

Мы предлагаем дипломы психологов, юристов, экономистов и других профессий по разумным тарифам.– universalnetworks.works/read-blog/4869_kupit-diplom-vracha.html

точные прогнозы на кхл https://www.luchshie-prognozy-na-khokkej12.ru .

заказать окна [url=https://02stroika.ru/]заказать окна[/url] .

прогнозы на периоды в хоккее http://luchshie-prognozy-na-khokkej12.ru .

unlimited bm facebook https://verified-business-manager-for-sale.org/

business manager for sale https://buy-business-manager-accounts.org/

buy tiktok ads https://buy-tiktok-ads-account.org

tiktok ads agency account https://tiktok-ads-account-buy.org

Please let me know if you’re looking for a author for your site. You have some really great articles and I feel I would be a good asset. If you ever want to take some of the load off, I’d love to write some material for your blog in exchange for a link back to mine. Please blast me an email if interested. Many thanks!

buy tiktok ad account https://tiktok-ads-account-for-sale.org

buy tiktok business account buy tiktok ads

tiktok ad accounts https://buy-tiktok-ad-account.org

tiktok ads agency account https://buy-tiktok-ads-accounts.org

buy tiktok ads https://tiktok-ads-agency-account.org

buy tiktok ads accounts https://buy-tiktok-business-account.org

tiktok ads agency account https://buy-tiktok-ads.org

Your article helped me a lot, is there any more related content? Thanks!

Over the counter antibiotics pills: buy antibiotics online uk – buy antibiotics from india

Licensed online pharmacy AU: Buy medicine online Australia – Licensed online pharmacy AU

https://eropharmfast.com/# ed treatment online

PharmAu24: Pharm Au 24 – Pharm Au 24

ed online pharmacy low cost ed meds online where to buy ed pills

best online ed medication: Ero Pharm Fast – Ero Pharm Fast

pharmacy online australia: online pharmacy australia – Licensed online pharmacy AU

Ero Pharm Fast: Ero Pharm Fast – ed online pharmacy

https://eropharmfast.com/# ed online meds

Pharm Au24: pharmacy online australia – online pharmacy australia

buy antibiotics: Biot Pharm – buy antibiotics online

online pharmacy australia Pharm Au 24 Online drugstore Australia

best ed medication online: cheap ed drugs – erectile dysfunction medication online

http://eropharmfast.com/# Ero Pharm Fast

cheap ed pills: Ero Pharm Fast – Ero Pharm Fast

монтаж натяжных потолков липецк http://www.potolkilipetsk.ru .

buy antibiotics online cheapest antibiotics buy antibiotics over the counter

Online medication store Australia: Buy medicine online Australia – PharmAu24

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

https://eropharmfast.com/# buying ed pills online

Ero Pharm Fast Ero Pharm Fast cheapest ed treatment

Pharm Au24: Medications online Australia – pharmacy online australia

Thanks for the article https://l-spb.ru/

betwinner latest version download https://betswinner.bet .

Предлагаем услуги профессиональных инженеров офицальной мастерской.

Еслли вы искали ремонт холодильников gorenje адреса, можете посмотреть на сайте: ремонт холодильников gorenje сервис

Наши мастера оперативно устранят неисправности вашего устройства в сервисе или с выездом на дом!

стоматология стоимость http://www.stomatologiya-vladimir-2.ru .

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Предлагаем услуги профессиональных инженеров офицальной мастерской.

Еслли вы искали ремонт кофемашин philips, можете посмотреть на сайте: ремонт кофемашин philips

Наши мастера оперативно устранят неисправности вашего устройства в сервисе или с выездом на дом!

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

диплом купить в красноярске http://russia-diploma.ru/ .

аттестат купить за 11 класс аттестат купить за 11 класс .

Заказать диплом ВУЗа по доступной стоимости возможно, обращаясь к надежной специализированной компании. Мы оказываем услуги по продаже документов об окончании любых университетов РФ. Заказать диплом любого ВУЗа– artrp.5nx.ru/posting.php?mode=post&f=3&sid=7b445b92a742fe447951abd9f9c205a9

For more information https://l-spb.ru .

шкаф с рольставнями https://shkaf-parking-3.ru .

водопонижение котлована stroitelnoe-vodoponizhenie6.ru .

ai therapy app https://www.ai-therapist1.com .

система дренажа http://www.stroitelnoe-vodoponizhenie6.ru .

ai therapist bot https://www.ai-therapist1.com .

For more information https://tonersklad.ru .

Покупка официального диплома через надежную компанию дарит ряд преимуществ. Быстро купить диплом о высшем образовании: star-girl.ru/viewtopic.php?f=4&t=17005

There is obviously a bundle to know about this. I consider you made some good points in features also.

ai therapy http://ai-therapist6.com/ .

mental health chatbot http://mental-health1.com .

шкаф с рольставнями на парковку http://www.shkaf-parking-3.ru/ .

ai therapy bot ai-therapist6.com .

mental health support chatbot mental-health1.com .

Где приобрести диплом специалиста?

Приобрести диплом университета по доступной цене можно, обратившись к надежной специализированной фирме.: diplompro.ru

Мы изготавливаем дипломы любой профессии по приятным ценам. Дипломы изготавливаются на подлинных бланках государственного образца Приобрести диплом любого ВУЗа fastdiploms.com

888starz официальный сайт 888starz официальный сайт .

шкаф металлический в народный гараж шкаф металлический в народный гараж .

I have been exploring for a little for any high quality articles or blog posts in this sort of house . Exploring in Yahoo I at last stumbled upon this website. Studying this info So i am satisfied to express that I have a very excellent uncanny feeling I came upon exactly what I needed. I so much surely will make sure to do not overlook this web site and provides it a look on a relentless basis.

купить септик для частного дома недорого в московской области цены http://www.septik-pod-klyuch-1.ru .

Какой диплом лучше заказывать — бакалавра или специалиста? Купить диплом о среднем образовании

В 2025 году наличие диплома всё ещё остаётся основным фактором при приёме на работу, повышении по службе или получении лицензии. И если у вас нет нужного документа — это не повод терять время на долгие годы учебы.

✅ Решение есть — заказ диплома, полностью соответствующего оригиналу:

С печатями, подписями, голограммами,

Внесение в архив (по запросу),

Любой ВУЗ, колледж — по всей России и СНГ.

Для кого подойдёт?

Вас отчислили, но обучение практически завершено?

Поступили на хорошую работу, но нет диплома?

Нужен диплом для лицензирования, повышения, тендера?

Мы работаем без предоплаты (по договору или поэтапно) и гарантируем полную конфиденциальность. У нас нет шаблонов — каждый документ готовится индивидуально, с учётом всех нюансов.

Наши гарантии:

Реалистичный диплом, неотличимый от оригинала

Настоящие данные выпускника (по вашей анкете)

Быстрая и надежная доставка по России и СНГ

Юридически грамотно оформленный договор (по желанию)

Мы сотрудничаем с квалифицированными специалистами, которые понимают, как должен выглядеть официальный документ — вплоть до мельчайших деталей. У нас много лет опыта и более random00..3999] довольных клиентов.

?? У кого в дипломе хоть раз была правда?

Вот реально: вы когда-нибудь смотрели свой диплом и думали — “да, всё, что здесь написано, я действительно знаю и умею”?

У многих — только бумажка. Корочка, глянцевая, с гербом и подписями, которую HR пролистывает за 1,5 секунды. А потом начинается: опыт, кейсы, компетенции, “что умеешь по факту?”. Диплом где-то там, в мнимом мире.

Но реалия в том, что без диплома тебе даже не дадут шанс доказать, что ты умеешь.

Ты можешь быть крутым специалистом, уметь в IT, дизайн, управление, логистику — но без документа с золотым тиснением не попадешь на собеседование.

?? Нормально ли это? Нет. Реальность ли это? Да.

Вот потому и появляются услуги, которые дают предложение:

“Не хочешь тратить 5 лет ради корочки? Мы поможем. Тебе нужен не вуз — тебе нужен диплом.”

Ты его получаешь, кладёшь в резюме, и дальше всё зависит от твоих мозгов, а не от шрифта на бумаге.

Кто-то скажет: “Это обман!”

А кто-то — “Это адаптация к системе, которая обманывает тебя с детства”.

?? И что в итоге?

Диплом становится не подтверждением знаний, а входным билетом. Как QR-код в метро — проверили, что есть, и пропустили.

Поэтому люди и покупают.

Не потому что глупые. А потому что взрослые, занятые, уставшие от лишнего.

Потому что хотят не учиться “ради процесса”, а работать по делу.

?? Ирония в том, что большинство таких дипломов — работают.

Даже если ты их не учил — ты знаешь, как применить. А вот “настоящие выпускники” потом всё равно идут на курсы и стажировки, потому что ничего не помнят.

И что важнее: корочка или то, как ты справляешься с задачей?

?? У кого были такие мысли — пишите. У кого был опыт — делитесь.

Можно ли заказывать диплом через посредника, и есть ли риски, что данные попадут не туда? Доступно тут

Рнтересует, можно ли сейчас купить диплом колледжа или техникума СЃ печатями Рё приложением, чтобы РѕРЅ прошёл официальную проверку? Доступ РїРѕ ссылке

В 2025 году наличие диплома всё ещё остаётся основным фактором при приёме на работу, повышении по карьерной лестнице или получении лицензии. И если у вас нет необходимого документа — это не повод терять годы.

✅ Решение есть — покупка диплома, полностью соответствующего оригиналу:

С печатями, подписями, голограммами,

Внесение в архив (по запросу),

Любой ВУЗ, колледж — по всей России и СНГ.

Для кого подойдёт?

Вас отчислили, но обучение практически завершено?

Нашли интересную работы, но нет “корочки”?

Нужен диплом для лицензирования, повышения, тендера?

Мы работаем без предоплаты (по договору или поэтапно) и гарантируем полную конфиденциальность. У нас нет шаблонов — каждый документ готовится индивидуально, с учётом всех нюансов.

Наши гарантии:

Диплом, неотличимый от оригинала

Настоящие данные выпускника (по вашей анкете)

Быстрая и надежная доставка по России и СНГ

Юридически грамотно оформленный договор (по желанию)

Мы сотрудничаем с квалифицированными специалистами, которые понимают, как должен выглядеть официальный документ — вплоть до мельчайших деталей. У нас много лет опыта и более random00..3999] довольных клиентов.

?? У кого в дипломе хоть раз была правда?

Серьезно: вы когда-нибудь смотрели свой диплом и думали — “да, всё, что здесь написано, я действительно знаю и умею”?

У многих — только бумажка. Корочка, глянцевая, с гербом и подписями, которую HR пролистывает за 1,5 секунды. А потом начинается: опыт, кейсы, компетенции, “что умеешь по факту?”. Диплом где-то там, в мнимом мире.

Но реалия в том, что без диплома тебе даже не дадут шанс доказать, что ты умеешь.

Ты можешь быть хорошим специалистом, уметь в IT, дизайн, управление, логистику — но без документа с золотым тиснением в кабинет не пустят.

?? Нормально ли это? Нет. Реальность ли это? Да.

Вот потому и появляются услуги, которые дают предложение:

“Не хочешь тратить 5 лет ради корочки? Мы решим вопрос. Тебе нужен не вуз — тебе нужен диплом.”

Ты его получаешь, кладёшь в резюме, и дальше всё зависит от твоих мозгов, а не от шрифта на бумаге.

Кто-то скажет: “Это обман!”

А кто-то — “Это адаптация к системе, которая обманывает тебя с детства”.

?? И что в итоге?

Диплом становится не подтверждением знаний, а входным билетом. Как QR-код в метро — проверили, что есть, и пропустили.

Поэтому люди и задумываются о покупке диплома.

Не потому что глупые. А потому что взрослые, занятые, уставшие от лишнего.

Потому что хотят не учиться “ради процесса”, а работать по делу.

?? Ирония в том, что большинство таких дипломов — работают.

Даже если ты их не учил — ты знаешь, как применить. А вот “настоящие выпускники” потом всё равно идут на курсы и стажировки, потому что ничего не помнят.

И что важнее: корочка или то, как ты справляешься с задачей?

?? У кого были такие мысли — пишите. У кого был опыт — делитесь.

Что делать, если купленный диплом оказался бракованным или не прошёл проверку? Мы поможем

Приобрести диплом университета по доступной цене вы можете, обратившись к проверенной специализированной фирме. Купить диплом: farmwoo.com/read-blog/32598_gde-kupit-nedorogoj-diplom.html

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Умные рулонные шторы для вашего дома, в интерьере.

Выберите рулонные шторы с электроприводом, максимальный комфорт.

Умные шторы: удобство на кончиках пальцев, в нашем интернет-магазине.

Умные рулонные шторы, отличный выбор.

Наслаждайтесь комфортом рулонных штор с электроприводом, ознакомьтесь.

Электрические рулонные шторы – удобство и стиль, подходят для любого окна.

Электроприводные рулонные шторы: инновации в вашем доме, решение для современного дизайна.

Электрические рулонные шторы: свобода выбора, познакомьтесь с нашими предложениями.

Электроприводные рулонные шторы: ваш лучший выбор, в нашем интернет-магазине.

Умные рулонные шторы: удобство и стиль, для вашего комфорта.

Электрические рулонные шторы – стиль и технология, с возможностью установки.

Электрические рулонные шторы для любого интерьера, выбор, который вы не пожалеете.

Электроприводные рулонные шторы: удобство управления одним нажатием, в вашем доме.

Электрические рулонные шторы для стиля и комфорта, закажите сейчас.

Рулонные шторы с электроприводом: комфорт на новом уровне, откройте для себя.

Электрические рулонные шторы – сочетание простоты и стиля, не упустите свой шанс.

Рулонные шторы с электроприводом для вашего комфорта, покупайте у нас.

Рулонные шторы с электроприводом: удобно и красиво, закажите прямо сейчас.

рулонные шторы с электроприводом рулонные шторы с электроприводом .

Электрические рулонные шторы, в интерьере.

Электроприводные рулонные шторы для вашего окна, интеллектуальное решение.

Электрические рулонные шторы для вашего дома, представлены.

Умные рулонные шторы, превосходное сочетание.

Время менять окна на рулонные шторы с электроприводом, смотрите.

Электрические рулонные шторы – удобство и стиль, создадут уют.

Электрические рулонные шторы: комфорт и уют, решение для современного дизайна.

Электрические рулонные шторы: свобода выбора, узнайте больше.

Рулонные шторы с электроприводом – элегантность и удобство, в нашем интернет-магазине.

Рулонные шторы с электроприводом для современного интерьера, которое вам понравится.

Электрические рулонные шторы – стиль и технология, предлагаемые с доставкой.

Умные рулонные шторы – правильно решайте, выбор, на который стоит обратить внимание.

Рулонные шторы с электроприводом – ваш идеальный помощник, в вашем доме.

Электрические рулонные шторы для стиля и комфорта, закажите сейчас.

Умные рулонные шторы для вашего удобства, сделайте свой дом комфортнее.

Умные рулонные шторы с электроприводом для вашего дома, не упустите свой шанс.

Рулонные шторы с электроприводом для вашего комфорта, выбирайте лучшее.

Электроприводные рулонные шторы для стильного дома, узнайте больше.

рулонные шторы с электроприводом рулонные шторы с электроприводом .

Рулонные шторы с электроприводом, инновации и дизайн.

Выберите рулонные шторы с электроприводом, максимальный комфорт.

Умные шторы: удобство на кончиках пальцев, в каталоге.

Современные рулонные шторы с электроприводом, идеальное решение.

Наслаждайтесь комфортом рулонных штор с электроприводом, ознакомьтесь.

Электрические рулонные шторы – удобство и стиль, создадут уют.

Электрические рулонные шторы: комфорт и уют, инновации, которые стоит попробовать.

Электрические рулонные шторы: свобода выбора, откройте для себя.

Электроприводные рулонные шторы: ваш лучший выбор, на нашем сайте.

Рулонные шторы с электроприводом для современного интерьера, которое вы заслуживаете.

Преобразите ваш дом с рулонными шторами с электроприводом, предлагаемые с доставкой.

Электрические рулонные шторы для любого интерьера, выбор, на который стоит обратить внимание.

Электроприводные рулонные шторы: удобство управления одним нажатием, носим с собой.

Электрические рулонные шторы для стиля и комфорта, закажите сейчас.

Рулонные шторы с электроприводом: комфорт на новом уровне, откройте для себя.

Умные рулонные шторы с электроприводом для вашего дома, пополните свой интерьер.

Рулонные шторы с электроприводом для вашего комфорта, заказывайте онлайн.

Электроприводные рулонные шторы для стильного дома, изучите сейчас.

рулонные шторы с электроприводом рулонные шторы с электроприводом .

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Рулонные шторы с электроприводом, в вашем пространстве.

Современные рулонные шторы с электрическим управлением, для вашего удобства.

Электрические рулонные шторы для вашего дома, в наличии.

Умные рулонные шторы, качества и стиля.

Наслаждайтесь комфортом рулонных штор с электроприводом, смотрите.

Умные рулонные шторы для дома, подходят для любого окна.

Электрические рулонные шторы: комфорт и уют, инновации, которые стоит попробовать.

Рулонные шторы с электроприводом для легкого управления, откройте для себя.

Электроприводные рулонные шторы: ваш лучший выбор, в каталоге товаров.

Электрические рулонные шторы: удобство на каждом окне, которое вам понравится.

Современные рулонные шторы с электроприводом, предлагаемые с доставкой.

Электрические рулонные шторы для любого интерьера, выбор, на который стоит обратить внимание.

Электроприводные рулонные шторы: удобство управления одним нажатием, в вашем доме.

Электрические рулонные шторы для стиля и комфорта, нажмите для подробностей.

Электрические рулонные шторы – стильный выбор, сделайте свой дом комфортнее.

Рулонные шторы с электроприводом – вашим окнам это нужно, пополните свой интерьер.

Электрические рулонные шторы: легкость управления, покупайте у нас.

Электроприводные рулонные шторы для стильного дома, изучите сейчас.

рулонные шторы с электроприводом рулонные шторы с электроприводом .

Электрические рулонные шторы, в вашем пространстве.

Выберите рулонные шторы с электроприводом, для вашего удобства.

Электрические рулонные шторы для вашего дома, в нашем интернет-магазине.

Умные рулонные шторы, отличный выбор.

Наслаждайтесь комфортом рулонных штор с электроприводом, нажмите для подробностей.

Умные рулонные шторы для дома, добавят стиля.

Электроприводные рулонные шторы: инновации в вашем доме, решение для современного дизайна.

Электрические рулонные шторы: свобода выбора, узнайте больше.

Рулонные шторы с электроприводом – элегантность и удобство, на нашем сайте.

Рулонные шторы с электроприводом для современного интерьера, которое вы заслуживаете.

Современные рулонные шторы с электроприводом, предлагаемые с доставкой.

Умные рулонные шторы – правильно решайте, выбор, который изменит ваш быт.

Рулонные шторы с электроприводом – ваш идеальный помощник, каждый день.

Умные рулонные шторы: будущее уже здесь, закажите сейчас.

Умные рулонные шторы для вашего удобства, откройте для себя.

Электрические рулонные шторы – сочетание простоты и стиля, не упустите свой шанс.

Умные рулонные шторы – ваш идеальный выбор, выбирайте лучшее.

Электроприводные рулонные шторы для стильного дома, узнайте больше.

рулонные шторы с электроприводом рулонные шторы с электроприводом .

Умные рулонные шторы для вашего дома, удобство и стиль.

Выберите рулонные шторы с электроприводом, для современного дома.

Рулонные шторы с электроприводом: удобство и стиль, представлены.

Электроприводные рулонные шторы, комфорта и эстетики.

Время менять окна на рулонные шторы с электроприводом, нажмите для подробностей.

Рулонные шторы с электроприводом для вашего интерьера, создадут уют.

Электроприводные рулонные шторы: инновации в вашем доме, выбор, который стоит сделать.

Умные рулонные шторы – ваш новый помощник, узнайте больше.

Сделайте свой дом умнее с рулонными шторами, в каталоге товаров.

Электрические рулонные шторы: удобство на каждом окне, которое вы заслуживаете.

Современные рулонные шторы с электроприводом, доступные для заказа.

Рулонные шторы с электроприводом: функциональность и стиль, выбор, который вы не пожалеете.

Умные рулонные шторы для современного дома, каждый день.

Умные рулонные шторы: будущее уже здесь, выберите свои.

Электрические рулонные шторы – стильный выбор, сделайте свой дом комфортнее.

Умные рулонные шторы с электроприводом для вашего дома, не упустите свой шанс.

Умные рулонные шторы – ваш идеальный выбор, выбирайте лучшее.

Преимущества рулонных штор с электроприводом, закажите прямо сейчас.

рулонные шторы с электроприводом рулонные шторы с электроприводом .

Электрические рулонные шторы, в вашем пространстве.

Электроприводные рулонные шторы для вашего окна, для современного дома.

Умные шторы: удобство на кончиках пальцев, у нас.

Умные рулонные шторы, идеальное решение.

Время менять окна на рулонные шторы с электроприводом, смотрите.

Умные рулонные шторы для дома, добавят стиля.

Электроприводные рулонные шторы: инновации в вашем доме, выбор, который стоит сделать.

Электрические рулонные шторы: свобода выбора, откройте для себя.

Электроприводные рулонные шторы: ваш лучший выбор, в нашем интернет-магазине.

Электрические рулонные шторы: удобство на каждом окне, которое вы заслуживаете.

Современные рулонные шторы с электроприводом, предлагаемые с доставкой.

Рулонные шторы с электроприводом: функциональность и стиль, выбор, который вы не пожалеете.

Электроприводные рулонные шторы: удобство управления одним нажатием, носим с собой.

Электрические рулонные шторы для стиля и комфорта, нажмите для подробностей.

Умные рулонные шторы для вашего удобства, сделайте свой дом комфортнее.

Умные рулонные шторы с электроприводом для вашего дома, не упустите свой шанс.

Умные рулонные шторы – ваш идеальный выбор, заказывайте онлайн.

Рулонные шторы с электроприводом: удобно и красиво, закажите прямо сейчас.

рулонные шторы с электроприводом рулонные шторы с электроприводом .

Умные рулонные шторы для вашего дома, в вашем пространстве.

Электроприводные рулонные шторы для вашего окна, максимальный комфорт.

Рулонные шторы с электроприводом: удобство и стиль, представлены.

Умные рулонные шторы, качества и стиля.

Изучите мир электрических рулонных штор, ознакомьтесь.

Рулонные шторы с электроприводом для вашего интерьера, создадут уют.

Электроприводные рулонные шторы: инновации в вашем доме, решение для современного дизайна.

Электрические рулонные шторы: свобода выбора, узнайте больше.

Электроприводные рулонные шторы: ваш лучший выбор, в каталоге товаров.

Рулонные шторы с электроприводом для современного интерьера, для вашего комфорта.

Современные рулонные шторы с электроприводом, предлагаемые с доставкой.

Умные рулонные шторы – правильно решайте, выбор, на который стоит обратить внимание.

Рулонные шторы с электроприводом – ваш идеальный помощник, каждый день.

Умные рулонные шторы: будущее уже здесь, нажмите для подробностей.

Рулонные шторы с электроприводом: комфорт на новом уровне, откройте для себя.

Рулонные шторы с электроприводом – вашим окнам это нужно, не упустите свой шанс.

Умные рулонные шторы – ваш идеальный выбор, выбирайте лучшее.

Электроприводные рулонные шторы для стильного дома, закажите прямо сейчас.

рулонные шторы с электроприводом рулонные шторы с электроприводом .

Лучшие казино онлайн в Беларуси, открывайте новые возможности, бесподобные акции.

Откройте для себя казино Беларуси, в удобное для вас время, для всех игроков.

Выигрывайте легко в белорусских казино, проверенное время, достигайте успеха.

Онлайн-казино, которым можно доверять, высокие выплаты.

Широкий выбор игр в белорусских казино, от карточных до настольных игр, на любой вкус.

Откройте для себя новинки в казино, для азартных геймеров.

Поспешите за бонусами в казино онлайн, только для вас.

Топ онлайн-игр в белорусских казино, готовы порадовать, погрузитесь в увлекательные приключения.

Как выбрать лучшее казино, по азартным играм.

Ваш шанс на удачу здесь, получайте незабываемые эмоции.

казино беларусь казино беларусь .

Онлайн-казино для белорусов, открывайте новые возможности, порадуют вас.

Играйте в казино онлайн в Беларуси, в удобное для вас время, для всех игроков.

Реальные выигрыши в онлайн-казино, заведомо безопасно, достигайте успеха.

Рейтинг лучших казино Беларуси, каждый день.

Играйте в любимые игры в казино онлайн, от слотов до покера, для истинных ценителей.

Откройте для себя новинки в казино, лицензированные операторы.

Не упустите свои шансы на бонусы, подарки для новых игроков.

Захватывающие новинки игр, всегда готовы к игре, откройте для себя мир азартных игр.

Как выбрать лучшее казино, по азартным играм.

Станьте частью захватывающего мира казино, получайте незабываемые эмоции.

казино казино онлайн .

Лучшие казино онлайн в Беларуси, получайте удовольствие от игры, ждут вас.

Играйте в казино онлайн в Беларуси, все время на связи, для всех игроков.

Выигрывайте легко в белорусских казино, заведомо безопасно, достигайте успеха.

Самые надежные онлайн-казино в Беларуси, высокие выплаты.

Широкий выбор игр в белорусских казино, от рулетки до блэкджека, для азартных игроков.

Свежие предложения в мире азартных игр, лицензированные операторы.

Поспешите за бонусами в казино онлайн, только для вас.

Лучшие игры года , уже ждут вас, откройте для себя мир азартных игр.

Советы по выбору казино, по азартным играм.

Станьте частью захватывающего мира казино, играйте ответственно.

казино казино онлайн .

Онлайн-казино для белорусов, получайте удовольствие от игры, порадуют вас.

Играйте в казино онлайн в Беларуси, все время на связи, выгодные предложения.

Реальные выигрыши в онлайн-казино, лицензированные заведения, играйте ответственно.

Рейтинг лучших казино Беларуси, ежедневно.

Широкий выбор игр в белорусских казино, от слотов до покера, для азартных игроков.

Новые онлайн-казино Беларуси, популярные игры.

Соберите все бонусы и акции, только для вас.