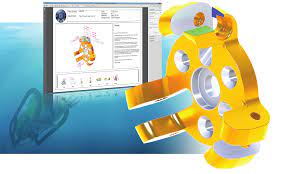

SOLIDWORKS MBD

Define, Organize, and Publish 3D Product Manufacturing Information (PMI)

What is SOLIDWORKS MBD?

If one is looking to create directly in 3D, rather than 2D drawings, all in industry standards, then SOLIDWORKS MBD is the software to count! One can define, organize and publish all product manufacturing information and this helps to accelerate time to market, improves efficiency and streamlines all production processes.

TOOLS

Define and Organize 3d PMI

All product information can be defined, and a bill of materials can also be defined and generated. Drawings and models can be organized and searched easily.

Customized Output Templates

Any 3D output template can be customized for multiple stakeholders, departments, and processes.

Share 3D data and PUBLISH 3d PDF DRAWINGS

3D PDFs and edrawings can be generated. Further, 3D drawings can be directly worked on to minimize time spent on 2D drawings. All relevant industry standards are also supported.

SOLIDWORKS MBD FEATURES

CREATE 3D PMI SEAMLESSLY

Create precise 3D product manufacturing information and stop relying on 2D drawings!

SHARE YOUR FILES

SOLIDWORKS MBD can add 3D PMI to standard file formats and this can subsequently be shared to all stakeholders, departments, suppliers etc.

COMPARE SOLIDWORKS MBD

| SOLIDWORKS MBD | TRADITIONAL SOLIDWORKS |

|

3D PRODUCT MANUFACTURING INFORMATION (PMI) DEFINITION |

||

| Intelligent Dimensioning, Tolerancing, and Annotation (DimXpert) Freestyle Dimensioning, Tolerancing, and Annotation (Reference Dimensions) Comprehensive Bill of Materials (BOM) |

3D PMI ORGANIZATION |

||

| 3D Annotation Views | ||

Automatic Show and Hide Annotations as a Model Rotates |

||

3D Views capturing Annotation Views, Configurations, Display States, Section View, and other View Settings |

||

3D Model Break Views |

||

3D Radial Explode Views |

3D OUTPUT |

||

Publish to eDrawings |

||

3D Output Template Customization |

||

Rich Predefined 3D Output Templates |

||

3D PDF with 3D PMI, Views, and Meta Properties |