When analyzing stress on a structure, engineers rely on two key methods: von Mises stress and principal stress. While both visualize stress distribution, they offer distinct insights.

This comparison explores the fundamental differences between Von Mises and principal stress plots, highlighting their strengths and guiding you on which approach best suits your material and analysis goals.

It’s a bit tricky right? Especially for New FEA Engineers. Let’s dive to understand the difference

Von Mises Stress: A Distortion Energy Measure

While not a true stress, It represents the distortion of energy density at a specific point. It helps predict failure in ductile materials (materials that deform before breaking).

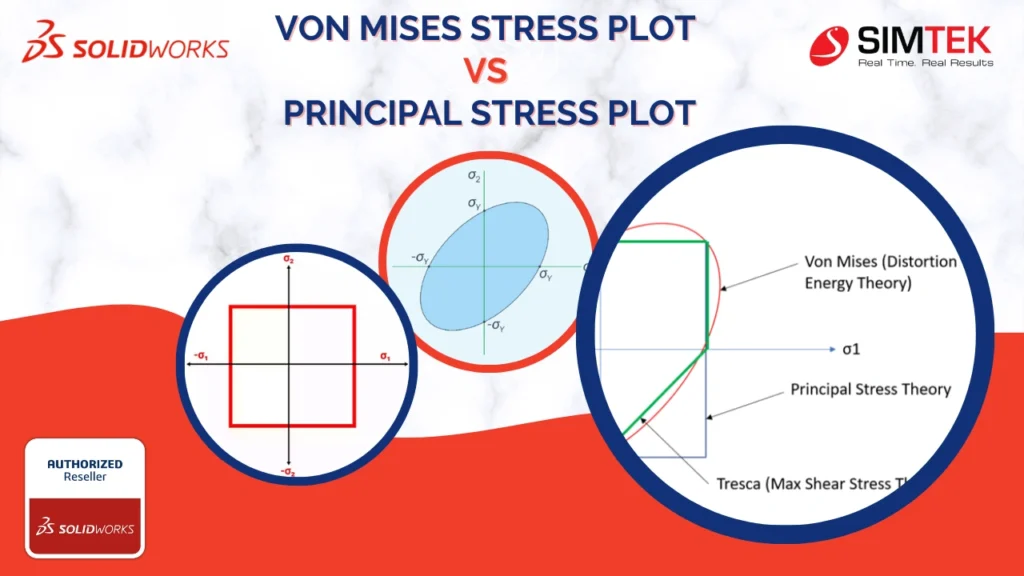

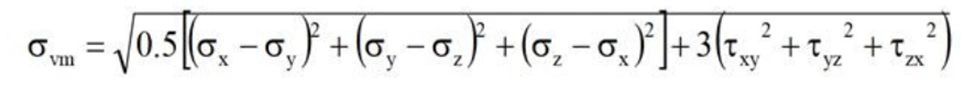

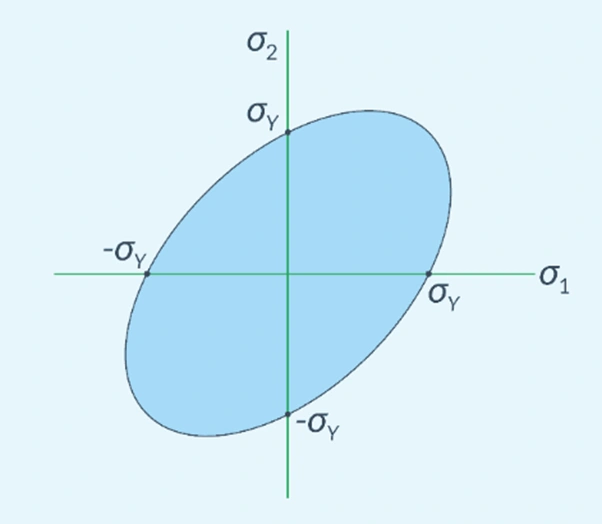

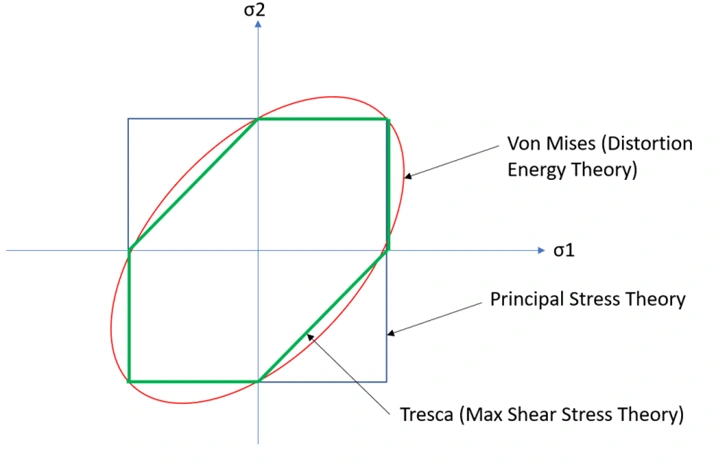

Richard von Mises observed that even when individual principal stresses stay below the material’s yield point, their combined effect can still cause yielding. He proposed a formula to combine the three principal stresses into an equivalent stress.

This equivalent stress is then compared to the material’s yield stress to assess the risk of failure using the von Mises criterion.

Principal Stresses: The “True” Stresses

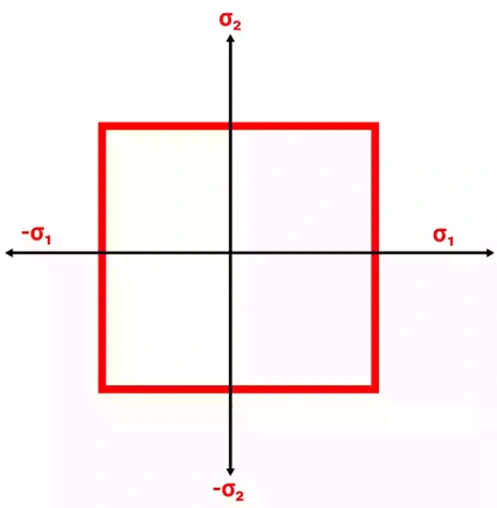

Principal stresses, on the other hand, are genuine stresses obtained by rotating a stress element to eliminate shear stress. The resulting normal stresses are called principal stresses. They represent the maximum normal (tensile or compressive) stresses an element can experience under specific loads.

A failure theory based on principal stresses is the maximum principal stress theory. This theory suggests that brittle materials fail when the largest principal stress reaches the ultimate tensile strength. While well-supported by experiments, it assumes equal tensile and compressive ultimate strengths, which isn’t always the case.

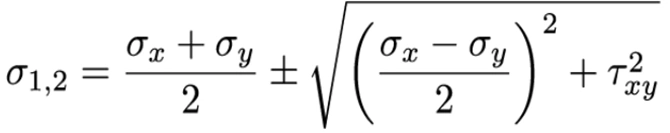

Formula for Principal Stresses:

Choosing the Right Tool: Von Mises vs. Principal Stress:

For ductile materials, the von Mises theory is generally preferred due to its accuracy in predicting deformation. However, principal stress plots remain valuable for analyzing brittle materials and understanding potential fracture points.

Conclusion :

In general, It is considered to be a more accurate measure of a material’s resistance to deformation, while Principle stress is more useful in predicting failure in brittle materials.