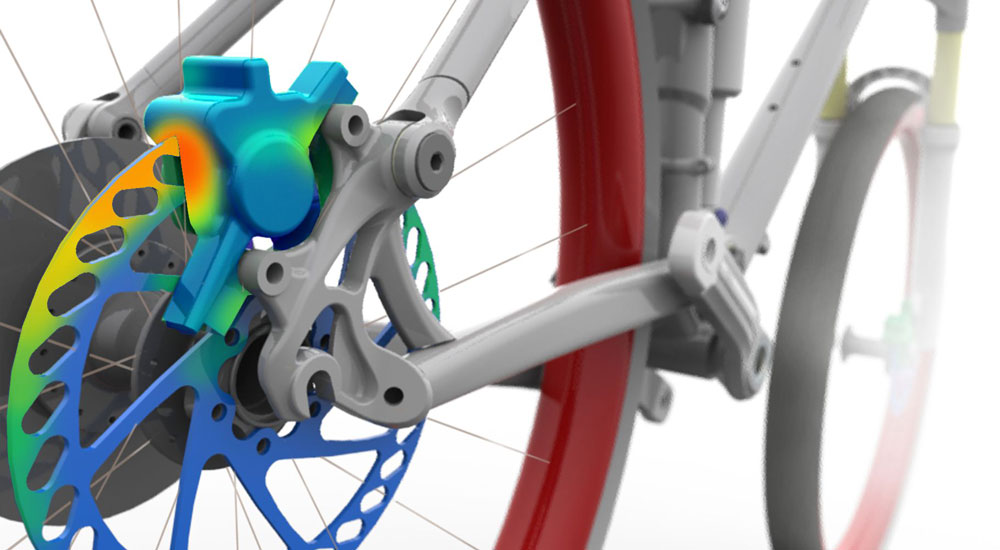

SOLIDWORKS Simulation

Subject your designs to real world conditions to raise product quality while reducing

prototyping and physical testing costs.

Concept to Perfection: Virtual Testing with SOLIDWORKS Simulation

Why Choose SOLIDWORKS Simulation?

Benefits of SOLIDWORKS Simulation

Cut Costs and Reduce Prototypes

SOLIDWORKS Simulation helps eliminate the need for multiple physical prototypes by allowing engineers to test virtually. With digital simulation, design teams can iterate quickly and identify flaws early—saving time, material, and manufacturing costs. In many cases, companies reduce their physical prototypes to just one final test, significantly lowering overall development expenses.

Accelerate Product Development

By simulating and validating designs early in the process, development cycles become faster and more efficient. Engineers can make quick design changes without waiting for physical models. In fact, companies that have adopted SOLIDWORKS Simulation with cloud collaboration tools have reported up to 20% faster development and 40% lower prototyping costs.

Foster Design Innovation

With the ability to virtually explore different configurations, materials, and stress points, SOLIDWORKS Simulation gives designers the freedom to innovate safely. Whether optimizing for weight, strength, cost, or efficiency, engineers can push boundaries without risking costly failures.

Improve Design Reliability

Early detection of structural or motion-related issues ensures better product integrity before anything reaches the production stage. Simulation enables thorough testing of real-world conditions, leading to fewer design errors, more dependable products, and a better customer experience.

Reduce Risk and Ensure Compliance

Virtual testing allows teams to validate products against safety, performance, and compliance standards before they hit the market. This proactive approach minimizes late-stage surprises and helps avoid expensive redesigns. By building confidence into every step, SOLIDWORKS Simulation ensures products are market-ready from the start.

Enhance Collaboration Across Teams

SOLIDWORKS Simulation fosters better communication and collaboration between design, engineering, and manufacturing teams. With simulation tools integrated directly into the SOLIDWORKS 3D CAD environment, everyone works with the same data and models—ensuring consistency, reducing errors, and speeding up approvals. Whether you’re working onsite or across locations, shared simulation insights help teams make smarter, unified decisions faster. For companies embracing digital transformation, this connected workflow is a game-changer.

Key Benefits of 3DEXPERIENCE SOLIDWORKS

| Feature | Description |

|---|---|

| Structural Analysis (FEA) | Evaluate stress, strain, and displacement under loads to ensure your product is structurally sound and safe for use. |

| Thermal Analysis | Simulate heat transfer and temperature effects to optimize thermal performance and material behavior in your design. |

| Frequency (Modal) Analysis | Identify natural vibration frequencies to avoid resonance issues and ensure design stability during operation. |

| Buckling Analysis | Detect structural buckling under compressive forces to prevent collapse or failure in load-bearing designs. |

| Drop Test Simulation | Simulate real-world impact scenarios to improve product durability and ensure better shock resistance. |

| Fatigue Analysis | Predict material fatigue from repeated stress cycles and estimate product life before failure. |

| Motion Simulation | Analyze moving assemblies to study forces, contact, velocities, and mechanical behavior in real time. |

| Nonlinear Analysis | Test components made from nonlinear materials or experiencing large deformations, such as plastics or rubber. |

| Optimization Tools | Automatically explore design variations to meet strength, weight, and cost goals using goal-driven optimization. |

| CAD-Integrated Workflow | Perform simulations directly in the SOLIDWORKS interface to streamline validation and accelerate design decisions. |

Ready to Bring Your Designs to Life — Virtually?

Cut costs, eliminate trial-and-error, and innovate faster with SOLIDWORKS Simulation. Whether you’re designing consumer products, industrial equipment, or automotive parts, our virtual testing solutions help you build smarter, stronger, and safer.

Get your personalized SOLIDWORKS Simulation quote today!

Start optimizing your designs with confidence — request your quote now!