SOLIDWORKS CAM AND CAMWORKS

SOLIDWORKS CAM and CAMWorks seamlessly integrate design and manufacturing by bringing advanced, rules-based CNC programming directly into the SOLIDWORKS environment—empowering users of SOLIDWORKS and 3DEXPERIENCE SOLIDWORKS to machine smarter and faster with CAMWorks, developed by HCL Technologies.

What is SOLIDWORKS CAM?

SOLIDWORKS CAM is an add-on to all versions of SOLIDWORKS CAD that lets you prepare your designs for manufacturability earlier in the development cycle. Manufacturing tasks that had to wait until a design was complete can now be performed concurrently with the design process.

CAMWorks for 3DEXPERIENCE SOLIDWORKS, CAMWorks for SOLIDWORKS desktop, and SOLIDWORKS CAM provide a truly integrated, feature-based CADCAM solution for machine shops of all sizes. SOLIDWORKS CAM is powered by CAMWorks and is included in every seat of SOLIDWORKS version 2018 or later on subscription. SOLIDWORKS CAM includes 2.5 and 3-axis milling capabilities. Additional functionality – for 5-axis simultaneous milling, mill-turn, wire EDM, nesting, simulation, shop floor solutions, and more – are available in subsequent product levels of SOLIDWORKS CAM and CAMWorks.Reduce your programming time with fully-integrated CAD/CAM that eliminates the need to import and export CAD files into your CAM system. You no longer need to maintain separate CAD and CAM files because all your part data is stored in one file. Feature-based programming and automatic feature recognition also save programming time because CNC intelligence is built into the software to identify operations, tools, feeds/speed rates, and more. Achieve consistent, high-quality manufacturing with knowledge-based machining and the TechDB, which captures and reuses your best practices for consistent results. Tolerance-based machining helps achieve superior tolerance and surface finish requirements by reading MBD and PMI data and selecting the machining strategies to meet the specified tolerances. For more information, please visit www.simtek.in or email marketing@simtek.in

SOLIDWORKS CAM FEATURES

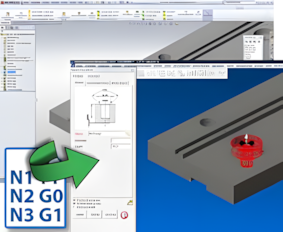

Full Integration

With an intuitive integration capability, design and manufacturing are both integrated into one system. Thus, there are huge savings in time, and all compatibility, import, and export issues are avoided.

Upon design creation, one can seamlessly switch over to the CAM environment and start creating tool paths for execution.

CAD Model & CAM Data are Parametrically Linked Together

Since the CAD and CAM parts are related, any changes in the CAD will also be updated in the CAM. Thus, there is no need for relooking the toolpaths as it is readily updated with the CAD is updated. This generates huge operational savings in time, effort, and money!

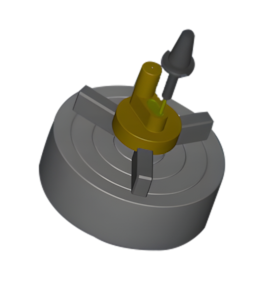

Advanced Feature-Based CAM Technology

- Automatic Feature Recognition. Any prismatic feature is recognized automatically and efficient toolpaths are created. This is also customizable. Parametric information is used to select proper cutting tools during the coding part, and it can be in line with the company standards and best practices as appropriate.

- Interactive Feature Recognition. This feature helps to generate efficient tool paths with a few clicks and offers endless customization and flexibility.

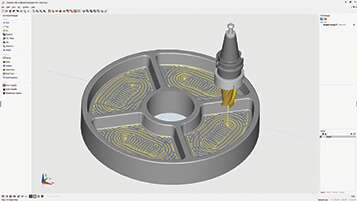

Toolpath Simulation

By using the integrated simulator avoids mistakes in real-time! All machining strategies can be verified, as well as the setup information for each component.

Knowledge-Based Machining

Users are empowered to create, save and edit SOLIDWORKS CAM data as appropriate. The same information is leveraged for use in future projects. All machining based on company standards and best practices can be saved and reused. SOLIDWORKS automatically picks this data from the database and helps create efficient toolpaths in an automated fashion.

CAD Agnostic

SOLIDWORKS supports projects developed on other CAD software and helps to create toolpath information. Easy imports mean that the software is CAD agnostic and extremely easy and flexible to use, operate and support.

FREQUENTLY ASKED QUESTIONS

What file type can I program?

If the file type can be brought into SOLIDWORKS as solid bodies or surfaces, it can be programmed.

What version of SOLIDWORKS do I need to access SOLIDWORKS CAM?

What about a post processor?

Post processors are information translators, converting SOLIDWORKS CAM data into G-Code that your machine controller can read. SOLIDWORKS CAM comes with many standard post processors, but custom posts can be purchased and supported through Simtek for more specialized needs.

Can I program assembly files with multiple parts and fixtures?

SOLIDWORKS CAM standard can only work with SOLIDWORKS part files. Though toolpaths can be patterned to represent multiple parts, the full assembly functionality, capable of representing fixturing and other advanced features is found in higher package levels.

SOLIDWORKS CAM VS CAMWORKS

SOLIDWORKS CAM |

CAMWORKS |

| Standard | Professional | Standard | Milling Standard | Milling Professional | Turning Standard | Turning Professional | Premium | Bundle Add-Ons | |

| 2.5 Axis Milling | |||||||||

| 2.5 Axis Volumill | |||||||||

| 3 Axis Milling – Level 1* | |||||||||

| Cimco Editor/DNC | |||||||||

| 3 Axis Milling – Level 1+* | |||||||||

| 4/5 Axis Indexing | |||||||||

| Turning | |||||||||

| Sub-Spindle | |||||||||

| Rotary Milling | |||||||||

| 3 Axis Milling – Level 2* | |||||||||

| Mill-Turn | |||||||||

| 3 Axis Milling – Level 3* with Undercutting | |||||||||

| Synchronous Machining for Lathes | |||||||||

| Virtual Machine Standard | |||||||||

| 4 Axis Milling (Add-On to Milling Pro only) | |||||||||

| 5 Axis Simultaneous | |||||||||

| 3 Axis Volumill | |||||||||

| Virtual Machine Professional | |||||||||

| Virtual Machine Premium | |||||||||

| NestingWorks** | |||||||||

| CAMWorks ShopFloor** | |||||||||

| PrimeTurning™Ɨ | |||||||||

| CAMWorks Utilities |

**Also available as independent base purchases. Ɨ PrimeTurning is a Sandvik Coromant product.

*3 Axis Milling Level 1 Includes Ara Clear Roughing, Flat Area and Z-Level Finishing

*3 Axis Milling Level 1+ Includes Level 1 functionality plus Z-Level Finishing with Constant Step-over

*3 Axis Milling Level 2 Includes Level 1+ functionality plus Pattern Project, Constant Step, Pencil Milling, Curve Project, and Legacy Rough & Finish Mill

*3 Axis Milling Level 3 Includes Level 2 functionality plus Undercutting, Fillet Machining, and True Surface Machining