Linking SOLIDWORKS Electrical 2D to 3D Assemblies

Step 1: Electrical 2D Project Should Be Created

- SOLIDWORKS Electrical 2D should be launched.

- A new project should be created by selecting “New Project” and choosing a template or starting from scratch.

- Schematics should be designed:

- Components, symbols, wires, and cables should be added.

- Circuits and terminal strips should be defined.

- The project should be saved, and manufacturer part numbers must be assigned to all components to ensure 3D integration compatibility.

Step 2: 3D Part Data Should Be Assigned to Components

The manufacturer part manager should be opened.

For each component:

- “Edit Part” should be selected, then navigated to the “SolidWorks Part” tab.

- A 3D model from the library should be assigned, or a custom one should be inserted.

- Mating points for wire connections must be defined properly.

Step 3: SolidWorks 3D Should Be Launched and the Electrical 3D Add-In Enabled

- SolidWorks 3D CAD should be opened.

- From the “Tools” > “Add-Ins” menu, SolidWorks Electrical 3D should be activated.

- The Electrical 3D tab should be accessed from the Command Manager.

Step 4: The 2D Project Should Be Linked in SolidWorks 3D

- In the Electrical 3D tab, “Open Electrical Project” should be clicked.

- The same project created in 2D should be located and opened.

- Upon loading, the following will be imported automatically:

- Component list

- Wiring data

- Cable references

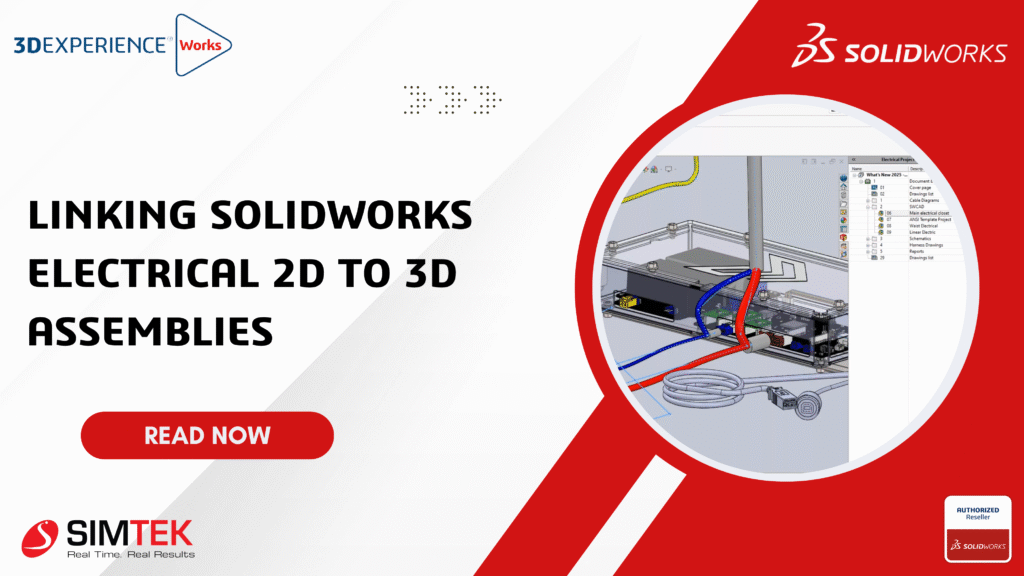

Step 5: Components Should Be Placed in the 3D Assembly

- A new assembly should be started, or an existing enclosure layout should be opened.

- The “Place Component” button should be used to insert parts defined in the 2D project.

- Components should be positioned and mated as needed within the cabinet or panel.

Step 6: Wires and Cables Should Be Routed in 3D

- The “Route Wires” or “Route Cables” function in the Electrical 3D tab should be clicked.

- The software will:

- Automatically generate paths between electrical connection points.

- Respect wire types and lengths defined in the 2D schematic.

- Routing paths can be manually adjusted using available Routing tools, if necessary.

Step 7: Reports Should Be Synced and Generated

The Electrical 2D project should be reopened.

- From the Project menu, “Update from 3D” should be selected to sync any changes made in 3D (e.g., lengths, locations).

- The following updated reports should be generated:

- Wire lists

- Cable summaries

- Cutting and routing reports

Final Checks

- The “Connection Report” should be used to verify schematic completeness.

- Wire lengths and 3D model accuracy should be carefully double-checked.

- The project can be exported in PDF, DWG, or STEP formats for sharing.

Conclusion

When SolidWorks Electrical 2D and 3D are linked, enhanced design integrity is achieved, collaboration between teams is improved, and production errors are significantly reduced. By following a streamlined workflow, smarter, cleaner, and more efficient control panels, harnesses, and assemblies can be delivered with confidence.