SIMTEK: Trusted Reseller of Cimatron CAM Software for Tooling

Looking for a reliable partner to streamline and elevate your CNC manufacturing processes with industry-leading CAM software?

SIMTEK is an authorized reseller of Cimatron—the most advanced, fully-integrated CAM platform designed specifically for toolmakers, mold manufacturers, die shops, and precision machining operations. Whether you’re a CNC programmer, tooling engineer, or a manufacturer seeking better throughput and surface quality, Cimatron CAM empowers your workshop with the tools needed for unmatched speed, accuracy, and efficiency.

Why Choose SIMTEK for Cimatron CAM?

- With over 25+ years of experience, SIMTEK delivers:

- CAM-focused software consultation & licensing

- End-to-end CAM implementation for mold, die & electrode machining

- Custom post-processors for multi-axis machines

- On-demand technical support and annual maintenance contracts

- CNC programming training for machinists and engineers

Why Engineers, Students & Enterprises Choose SIMTEK + Cimatron

- Best CAM tools for precision machining and fabrication

- Free Trail CAM software options for students and beginners (through academic licensing)

- Beginner-friendly CAM programming tools for educators and CNC trainees

- Professional CAM software for multi-axis toolpath generation and NC code output

- Auto-generating CNC toolpaths for molds, dies, and shop floor use

- Online CAM toolpath simulation tools for training and engineering workflows

- CAM software for Windows 11 with full 2.5D to 5-axis machining support

Buy Free Trail CAM Software with Professional Capabilities

While many free solutions offer limited CAM functions, Cimatron offers academic and trial licenses that allow students, educators, and evaluation users to buy free trail CAM software access—backed by SIMTEK’s implementation support.

✅ Ideal for students looking to master CAM

✅ Great for educators needing an industry-standard platform

✅ Perfect for startups evaluating CAM solutions without upfront investment

What Makes Cimatron CAM Stand Out?

Cimatron CAM is trusted by thousands of toolrooms and die shops for its powerful NC programming tools that support:

- 2.5-axis to full 5-axis CNC machining

- Toolpath optimization for faster cycle times

- Electrode machining with automation

- Mold and die roughing, semi-finishing, and finishing strategies

- Simulation and verification to avoid costly collisions

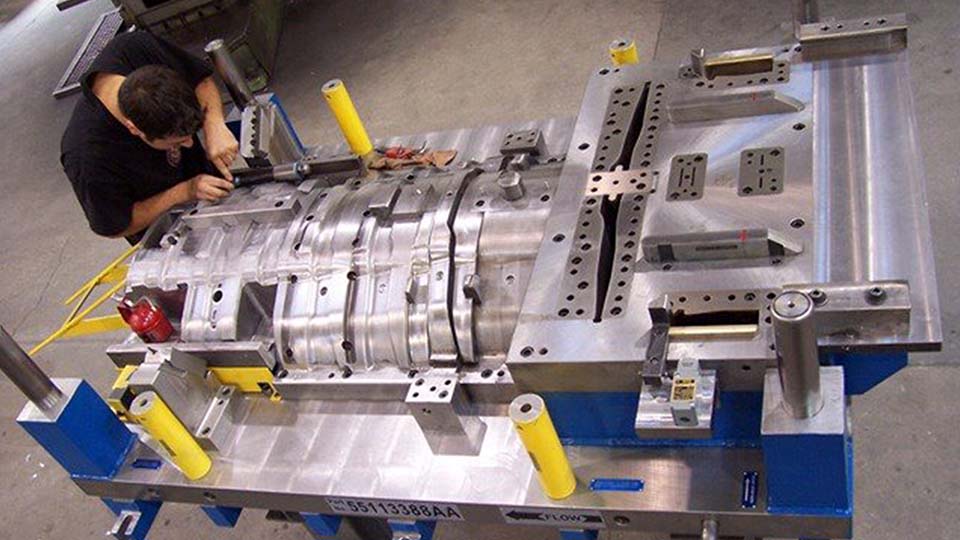

What Can You Do with Cimatron?

Dramatically increase your productivity, competitiveness, and profitability with a wide range of dedicated, applicative tools for mold, die, and electrode design and manufacturing, as well as a full range of CNC technologies, from simple 2.5-axis milling and drilling to complex 5-axis machining.

- Start working immediately with any input geometry.

- Deliver high-quality tools of any complexity or size with superb surface quality in record time.

- Shorten tool delivery time by up to 70 percent.

- Realize a return on investment (ROI) in six months or less.

- Easily handle engineering changes (ECOs).

Why Cimatron?

When it comes to tooling-focused CAM software, Cimatron is the trusted choice for mold shops, die manufacturers, and CNC machining professionals worldwide. It’s more than just CAM—it’s a productivity powerhouse tailored for the exacting demands of modern toolrooms and machine shops.

Training and Support from Tooling Experts

When you buy Cimatron CAM from SIMTEK, you’re supported by a team that lives and breathes tooling. Our experts deliver:

- Personalized onboarding for CAM users

- Application-specific training (mold, die, electrode, 5-axis strategies)

- Guidance on toolpath creation, roughing/finishing strategies, and NC code optimization

- Dedicated support for post-processors, upgrades, and machining issues

Boosts Machining Productivity

Cimatron CAM is engineered to reduce programming and machining cycles, helping you go from design to part faster. With automation features like toolpath templates, machining wizards, and intelligent feature recognition, you can:

- Accelerate quoting, programming, and tool delivery

- Reduce programming time and trial runs

- Increase machine uptime with error-free G-code generation

- Realize up to 70% reduction in lead times for mold and die manufacturing

Handles Any Geometry – Simple or Complex

Whether you’re machining basic prismatic parts or intricate 3D contoured surfaces, Cimatron CAM delivers accuracy and control. It’s ideal for:

- High-speed machining of plastic injection molds

- Progressive die components for metal stamping

- Multi-surface toolpaths for detailed wood or furniture carving

- Complex machine parts and undercut geometries

Machines Any Part

Cimatron’s integrated CAM module supports:

- 2.5-axis to full 5-axis CNC machining

- Optimized tool libraries (including Sandvik CoroPlus and others)

- Stock-aware toolpaths and automatic rest machining

- Real-time toolpath simulation to eliminate collisions and scrap

- Machine-ready G-code for nearly any CNC controller

One Integrated Solution—From Design to CNC Output

Cimatron unites CAM programming, toolpath simulation, and NC output in a single, robust platform. No third-party dependencies. No file conversions. No wasted time.

- One system for mold, die, electrode machining, and part finishing

- Seamless NC simulation, toolpath verification, and setup sheet generation

- Ideal for users searching for the best CAM software for CNC machine shops

- Enables you to buy free Trail CAM software licenses for evaluation or training via SIMTEK

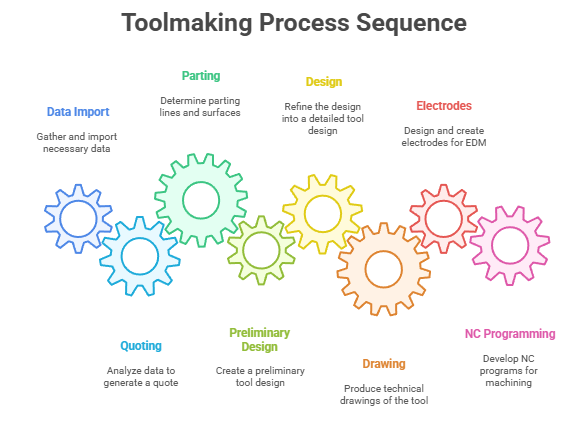

Here’s how CIMATRON & SIMTEK solves CAM Workflows

Support, speed and accuracy! SIMTEK always delivers, which is also Cimatron’s Advantage

In an industry where every second counts and every micron matters, using generic design tools is no longer enough. You need a solution engineered specifically for tooling challenges—from complex mold geometries to multi-axis CNC programming. Cimatron delivers exactly that, while SIMTEK ensures your team is fully equipped to master it—with localized support, structured training, and fast implementation. Whether you’re building dies, electrodes, or custom parts, we help you cut down design time, eliminate rework, and deliver with confidence.

We waste hours creating repetitive mold or die features

Reality: Toolmakers often redo the same mold bases, cooling layouts, sliders, and die punches—manually, project after project.

Impact: Reduced productivity, human error, and burnout.

✅ Solution: Intelligent Automation with Cimatron CAD-AI

Cimatron features CAD-AI automation that detects and applies tooling standards automatically—creating sliders, lifters, cavities, cores, and cooling channels with reusable templates.

Result: 50% faster tool design with consistency and compliance.

Our CNC programs crash or require constant rework

Reality: Many CAM operators face toolpath errors, missed features, or machine collisions due to limited software capabilities or lack of simulation.

Impact: Broken tools, scrap parts, machine downtime.

Solution: Advanced CAM Programming with Built-in Collision Detection

Cimatron’s CAM engine handles 2.5 to 5-axis programming, offers material removal simulation, and even integrates verified tool libraries like Sandvik CoroPlus.

Result: Accurate NC code, fewer reworks, and reduced machining time.

We don’t have access to reliable support or tooling-specific training

Reality: Generic CAD vendors or overseas support teams don’t understand your shop’s unique requirements.

Impact: Delayed resolutions, unsupported features, and frustrated teams.

Solution: Local Tooling Support from SIMTEK Experts

As a certified Cimatron reseller, SIMTEK provides personalized training, workflow-based onboarding, and local support from experts who’ve worked with hundreds of tool rooms, machine builders, and design firms.

Result: Confident users, productive shops, and long-term ROI.

We need software that our juniors and interns can also learn

Reality: Complex platforms come with a steep learning curve, especially for beginners or student interns.

Impact: Slower onboarding, wasted time, and training overload.

Solution: Easy-to-Learn CAD Tools + Step-by-Step Guidance

Cimatron provides an intuitive user interface with context-sensitive help, and SIMTEK supports your team with modular training programs—ideal for everyone from senior designers to freshers.

Result: Faster learning curve and wider team adoption.

Why Tooling Experts Trust SIMTEK

We Don’t Just Sell Software—We Enable Success

Over 25+ Years of Tooling Experience, Now Driving CAM Success

With 25+ years of hands-on expertise in die design, mold manufacturing, and multi-axis CNC programming, SIMTEK is the go-to partner for:

- Tool rooms & mold shops

- Precision CNC machining centers

- Product development teams

- Engineering colleges offering CAM education

We speak your language—tool offsets, cutter paths, surface finish issues, and tool wear patterns. That’s why India’s top tooling teams choose SIMTEK as their Cimatron CAM partner.

We Understand Tooling Because We’ve Lived It

At SIMTEK, we go beyond software distribution—we’re tooling veterans who’ve worked hands-on with mold makers, die engineers, and CNC programmers. We’ve faced toolpath crashes, tight machining deadlines, and design revisions at the last minute.

That’s why customers rely on us when they need:

- CAM software optimized for complex multi-axis operations

- Customized NC code for any machine controller

- Institutional licensing to buy free Trail CAM software for academic use

- Practical, in-depth CAM training for both new users and seasoned machinists

Beyond Software—We Boost Your Productivity

When you choose SIMTEK, you’re not just buying Cimatron—you’re gaining a partner who’s with you every step of the way. We start by understanding your needs, help you implement the software around your workflow, and train your team at a pace that fits. Whether it’s an ROI discussion, a quick support call, or deep technical help, we’re easy to reach, fast to respond, and always focused on your success. Your shop’s performance is our priority.

Real People. Real Results.

From large-scale automotive tooling companies to innovative startups and engineering institutions, SIMTEK has powered over 1000 CAM software deployments. What do they all share?

They needed trusted guidance, reliable technology, and the option to buy free Trail CAM software during initial onboarding or trials.

Here’s what they achieved:

- Faster production cycles with fewer machining errors

- Higher return on investment from CAM software and CNC hardware

- Cleaner toolpaths for 3-axis to full 5-axis machining

- Consistent post-sales support and technical assistance on demand

Request a Free Trial of Cimatron or a Free Quote

Looking to see how Cimatron fits your tooling workflow? We’ve made it easy.

Whether you want to explore the software hands-on or get pricing tailored to your business, SIMTEK is here to help you make the right move—with zero pressure.

Try Cimatron free Trail and experience its powerful CAM tools for mold, die, and NC programming

Request a quote built around your specific needs—no generic pricing, no guesswork

You’ll talk to real experts, not just salespeople. And we’ll walk with you every step of the way—from trial to training to full implementation.