CAE SERVICES

CAE Services

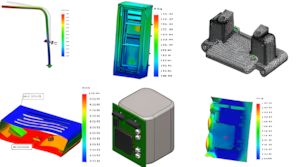

SIMTEK provides Computer-Aided Engineering (CAE) services that are used to solve complex engineering problems by breaking them down into manageable finite elements. CAE is used in a wide range of industries, including aerospace, automotive, energy, medical, electronics, and manufacturing. SIMTEK’s strengths in this field include decisions on the best design, fitness verification, predictive performance, component evaluation, etc.

Over the past 20 years, our dedicated engineers work with customers in areas like Product design & development, Finite element analysis (FEA), Design optimization, Computational Fluid dynamics (CFD), not only ensuring satisfactory results but also faster return on investment.

We also provide domain-specific CAE services, with experience in linear and non-linear analyses.

Solutions we provide:

structural analysis

thermal analysis

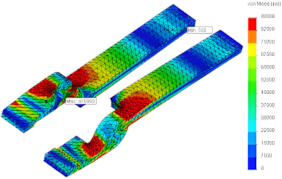

fatigue analysis

dynamic analysis

plastic flow analysis

internal & external fluid flow

design optimization

non linear analysis

motion/mechanism analysis

motion/topology study

Our Comprehensive CAE Services

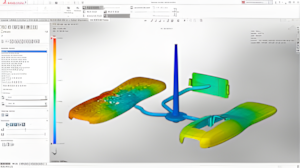

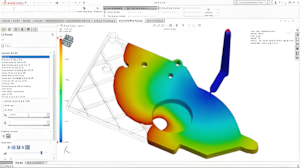

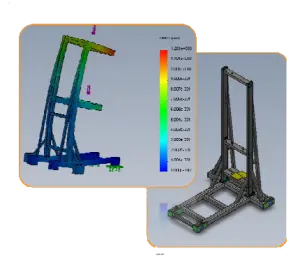

Structural Analysis

We employ advanced Finite Element Analysis (FEA) techniques to evaluate the structural integrity of your designs. Our analyses cover:

- Static and dynamic load simulations

- Stress and strain analysis

- Fatigue and fracture mechanics

- Vibration and modal analysis

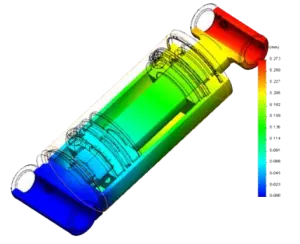

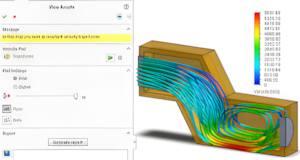

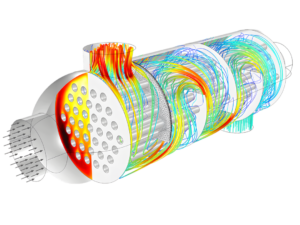

Fluid Dynamics (CFD)

Our Computational Fluid Dynamics simulations provide deep insights into fluid flow behaviors, including:

- Aerodynamics and hydrodynamics

- Heat transfer and thermal management

- Multiphase flow analysis

- HVAC system optimization

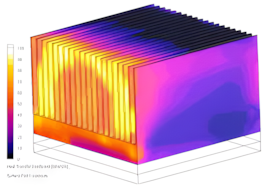

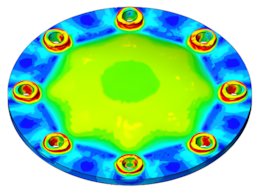

Thermal Analysis

We simulate heat transfer and thermal behaviors to optimize thermal management in your designs:

- Steady-state and transient thermal analysis

- Conjugate heat transfer

- Thermal stress analysis

- Electronics cooling simulations

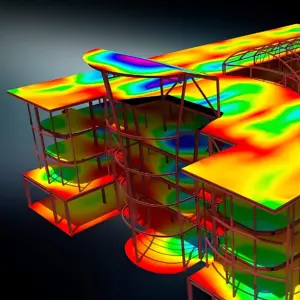

Multiphysics Simulations

Our expertise extends to complex multiphysics problems, coupling various physical phenomena:

- Fluid-structure interaction (FSI)

- Electromagnetics and RF simulations

- Acoustics and noise analysis

- Coupled thermal-structural analysis

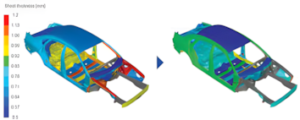

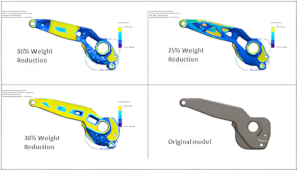

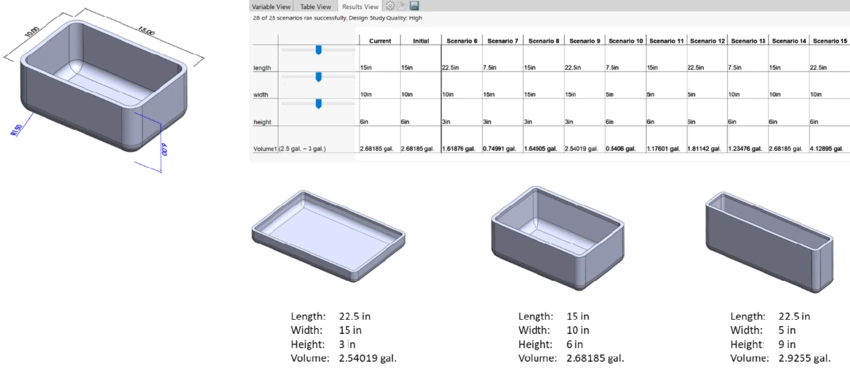

Optimization and Parametric Studies

We help you find the best design solutions through:

- Topology optimization

- Shape and size optimization

- Design of Experiments (DOE)

- Sensitivity analysis

Industry Applications

Our CAE services cater to a wide range of industries, including:

- Automotive: Vehicle dynamics, crash simulations, NVH analysis

- Aerospace: Structural integrity, aerodynamics, composite materials analysis

- Consumer Products: Drop test simulations, ergonomics studies

- Industrial Machinery: Machine dynamics, process simulations

- Energy: Wind turbine analysis, solar panel efficiency studies

- Electronics: Thermal management, EMI/EMC analysis

CUSTOMER SUCCESS STORIES

Mechasoft

MECHASOFT established in year 2004 as CAD/CAM Solution provider who has Die and pattern making facility and

Read more…

Bailey Hydropower Pvt Ltd.

Wayne Burt Systems, Inc – Atlanta based US corporation having state of art manufacturing facilities in

Read more…

Ceeyes Metals Reclamations Pvt Ltd.

Ceeyes Metals Reclamations Pvt Ltd established in year 1991, started Started out as a private firm with an objective to

Read more…

FAQs

What types of CAE analyses do you offer?

We offer a wide range of analyses including structural, fluid dynamics, thermal, multiphysics, and optimization studies. Our expertise covers most engineering simulation needs.

How accurate are CAE simulations?

CAE simulations can be highly accurate when properly set up and validated. We ensure accuracy through rigorous validation processes and correlation with physical tests when possible.

Can CAE replace physical testing?

While CAE significantly reduces the need for physical testing, it typically complements rather than completely replaces it. CAE can guide physical testing, making it more focused and efficient.

How long does a typical CAE project take?

Project duration varies based on complexity. Simple analyses might take a few days, while complex multiphysics simulations could require several weeks. We provide detailed timelines during project scoping.

Do you provide support for interpreting CAE results?

Absolutely. We don’t just deliver raw data; we provide comprehensive interpretation, clear visualizations, and actionable recommendations based on the simulation results.