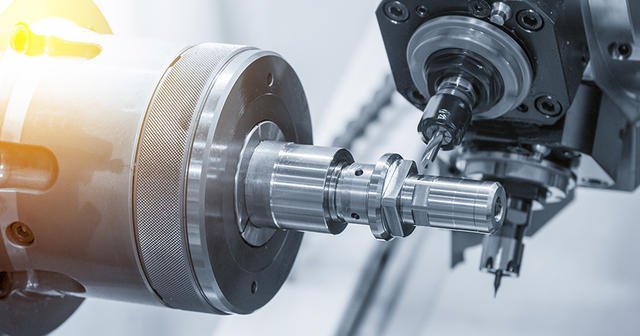

Advanced CNC Programming That Delivers Accuracy, Speed and Confidence

GibbsCAM CNC Programming Software for Milling, Turning and 5-Axis Machines in India

SIMTEK proudly brings GibbsCAM CNC programming software for milling, turning and 5-axis machines in India, helping manufacturers program faster, reduce machine downtime, and produce better quality parts with confidence.

Whether you run a CNC job shop, an OEM production facility, or a precision manufacturing unit, GibbsCAM gives you a powerful, reliable, and easy-to-use CAM platform that adapts to your real shop-floor workflow.

Start a Free GibbsCAM Trial — Built for High-Performance CNC Machining

Why CNC Shops in India Are Switching to GibbsCAM

Indian manufacturers face intense pressure:

- Tight delivery schedules

- Rising raw material costs

- High machine hour expenses

- Skilled programmer shortages

Traditional CAM software makes this worse by forcing programmers to:

- Manually edit code

- Use unreliable post-processors

- Perform trial cuts

- Risk tool crashes

This leads to lost production time, scrap, and frustrated teams.

GibbsCAM solves this problem.

It is a machine-centric CNC programming software designed to create clean, efficient and safe NC code — the first time.

What Is GibbsCAM?

GibbsCAM is a professional CAM software for CNC machines used by manufacturers around the world for milling, turning, mill-turn, Swiss-type and 5-axis machining.

Unlike generic CAM systems, GibbsCAM understands:

- CNC machine kinematics

- Turret and spindle configurations

- Tool changers

- Real-world machine limits

This allows it to generate machine-ready programs that require minimal editing and run smoothly on the shop floor.

Why GibbsCAM Is the Best CNC Programming Software in India

GibbsCAM is the leading CNC programming software for milling, turning and 5-axis machines in India, trusted by manufacturers who need powerful, reliable CAM software for CNC production. Built specifically for real shop-floor machining, GibbsCAM delivers fast CNC programming, accurate post-processing and true machine simulation—making it the preferred CAM software for Indian job shops, OEMs and high-precision manufacturing companies.

Faster Programming

GibbsCAM, the leading CNC programming software for milling, turning and 5-axis machines in India, reduces programming time by up to 50%, allowing programmers to complete more jobs faster while maintaining high accuracy and efficiency.

Accurate Post-Processors

SIMTEK delivers machine-specific CNC post-processors for FANUC, Siemens, Mitsubishi, Mazak, Haas, DMG Mori and more, making GibbsCAM the most reliable CAM software for CNC machines in India for real-world shop-floor production.

Collision-Free Simulation

With GibbsCAM’s true machine simulation, manufacturers using CNC programming software for milling, turning and 5-axis machining in India can detect errors early, prevent crashes, reduce scrap, and maximize CNC uptime and machining reliability.

Perfect for Multi-Axis

GibbsCAM is one of the best 5-axis CAM software solutions in India, trusted by manufacturers who require powerful multi-axis CNC programming to machine complex parts accurately, efficiently, and safely with complete production confidence.

Complete CAM Software for Milling, Turning and 5-Axis CNC Machines

GibbsCAM is the most powerful CNC programming software for milling, turning and 5-axis machines in India, designed to handle everything from simple prismatic parts to highly complex multi-axis components. As a professional CAM software for CNC machines, GibbsCAM gives manufacturers a single, unified platform to program, simulate and run production with speed, accuracy and confidence.

GibbsCAM supports a full range of CNC machining operations:

- 2-axis and 3-axis milling using advanced CAM software for CNC milling machines in India

- High-speed machining with optimized toolpaths for faster cutting and better surface finish

- CNC turning using precision CAM software for CNC lathe programming

- Mill-turn operations with integrated CNC programming software for milling and turning machines

- Multi-turret and multi-spindle lathes with synchronized CAM toolpath control

- Swiss-type CNC machines using specialized CAM software for Swiss machining

- 4-axis and 5-axis machining with industry-leading 5-axis CAM software for complex CNC parts

Whether you run a job shop, OEM production facility, or high-precision manufacturing unit, GibbsCAM gives you the most reliable CNC programming software for milling, turning and 5-axis machines in India—fully capable of handling complex toolpaths, tight tolerances, and demanding production schedules.

How GibbsCAM Improves Your Business

Using GibbsCAM CNC programming software for milling, turning and 5-axis machines in India, manufacturers gain a powerful advantage in today’s competitive CNC manufacturing environment. GibbsCAM is not just a CAM system—it is a complete productivity platform for CNC machine shops, OEMs and precision engineering companies looking to reduce costs, increase output and deliver higher-quality parts faster.

By using CAM software for CNC machines in India that is built around real shop-floor conditions, GibbsCAM helps businesses eliminate the delays, errors and inefficiencies that normally slow down CNC production.

With GibbsCAM, manufacturers consistently achieve:

- Shorter cycle times by using optimized toolpaths created by advanced CNC programming software for milling, turning and 5-axis machining

- Higher spindle utilization through faster setup, better NC code, and reduced machine idle time

- Reduced scrap and rework thanks to accurate post-processors and collision-free CNC simulation

- Faster order completion with reliable CAM software for CNC production that minimizes trial-and-error

- More profitable machine hours by maximizing uptime on CNC lathes, machining centers and multi-axis machines

- Lower stress on programmers through intuitive workflows and dependable CNC programming results

By using GibbsCAM CNC programming software for milling, turning and 5-axis machines in India, manufacturers can take on more complex jobs, deliver tighter tolerances, and improve customer satisfaction without increasing shop-floor risk.

This is not just CAM — it is a productivity engine that drives efficiency, profitability and growth for your CNC manufacturing business.

Why GibbsCAM Is One of the Best CAM Software Solutions

Choosing the best CAM software for CNC machining is not just about toolpaths—it’s about reliability, efficiency, and long-term productivity. GibbsCAM consistently ranks as one of the top CAM solutions because it is built for professional manufacturing environments.

1. True Manufacturing Intelligence

GibbsCAM understands machining, not just geometry. Its engine accounts for:

- Tool and holder clearance

- Stock conditions

- Machine kinematics

- Cutting forces and material behavior

This results in safer, faster, and more efficient toolpaths.

2. Shorter Programming Time

GibbsCAM’s intuitive workflow allows programmers to go from CAD model to G-code in significantly less time compared to many other CAM systems. That means:

- Faster job turnaround

- Lower programming costs

- More spindle uptime

3. Machine-Specific Post Processing

Every CNC machine is different. GibbsCAM uses highly customizable post processors to ensure the G-code matches your exact machine, controller, and tooling configuration—eliminating crashes and rework.

4. Proven in Production

From job shops to aerospace manufacturers, GibbsCAM is trusted worldwide for high-precision and high-volume machining

CNC Capabilities – From 3-Axis to 5-Axis and Beyond

GibbsCAM CAM software is a powerful, industry-proven CNC programming software designed to handle everything from simple 3-axis milling to advanced 5-axis CNC machining and mill-turn operations. As one of the best CAM software solutions for CNC machining, GibbsCAM supports nearly every machining scenario used in modern manufacturing environments.

3-Axis Milling CAM Software

GibbsCAM is a highly efficient CAM software for 3 axis CNC machining, ideal for day-to-day production and precision manufacturing.

Best suited for:

- Prismatic parts

- Fixtures and tooling

- Plates and brackets

- General CNC machining

GibbsCAM delivers advanced roughing, finishing, drilling, contouring, and pocketing toolpaths, enabling faster programming, reduced cycle times, and accurate G-code generation for 3-axis CNC machines.

4-Axis CNC Machining

With full rotary axis control, GibbsCAM supports both indexed and continuous 4-axis CNC programming, making it a reliable CAM solution for more complex geometries.

Ideal for:

- Complex prismatic components

- Engraving applications

- Rotary milling operations

GibbsCAM’s intelligent toolpath control ensures smooth motion, precise indexing, and safe machining on 4-axis CNC machines.

5-Axis CNC Machining Software

For manufacturers working in aerospace, medical, and high-precision industries, GibbsCAM is a leading CAM software for 5 axis CNC machining.

Advanced 5-axis capabilities include:

- Swarf cutting

- Multi-axis surface and contour finishing

- Collision-free toolpath generation

- Accurate machine kinematics handling

These features make GibbsCAM one of the best CAM software platforms for complex 5-axis CNC programming.

Turning & Mill-Turn CNC Programming

In addition to milling, GibbsCAM is a complete CNC programming software for turning and mill-turn machines, supporting:

- CNC turning operations

- Live tooling

- Multi-turret and multi-spindle machines

- Swiss-type lathes

With full synchronization and machine-aware toolpaths, GibbsCAM ensures safe, efficient, and optimized machining for advanced turning and multi-tasking CNC machines.

With its wide-ranging capabilities, GibbsCAM stands out as one of the most complete and reliable CAM software solutions for CNC machining, trusted by manufacturers worldwide.

Explore advanced programming strategies for multi-channel turn-mill centers that optimize cycle time, improve part quality, and drive higher profitability.

GibbsCAM Pricing & Licensing Overview

GibbsCAM pricing is designed to be flexible and scalable based on your manufacturing needs. There is no one-size-fits-all license because every shop uses different machines, axes, and features.

Your GibbsCAM pricing depends on:

- Number of axes (3-axis, 4-axis, 5-axis)

- Milling, turning, or mill-turn modules

- Post processors

- Simulation and verification options

SIMTEK helps you select the right configuration so you only pay for what you actually need—no unnecessary features, no wasted budget.

Why Manufacturers Choose GibbsCAM at SIMTEK

Across today’s high-pressure manufacturing world, CNC shops are expected to machine faster, cut more accurately, and deliver flawless parts — all while protecting machines, tools, and margins. That’s exactly why leading manufacturers choose GibbsCAM at SIMTEK as their best CAM software for CNC machining.

GibbsCAM CAM software isn’t just another CNC programming tool. It is a production-proven platform trusted by aerospace, automotive, mold & die, and precision engineering companies around the world. From simple 3-axis components to complex 5-axis aerospace parts, GibbsCAM creates intelligent, machine-aware toolpaths that run exactly as programmed — safely, smoothly, and efficiently.

But software alone does not deliver success. What truly sets SIMTEK apart is our role as an Authorized GibbsCAM Partner and a SIMTEK trusted partner of GibbsCAM. We don’t sell licenses — we build CNC performance. Every GibbsCAM system we deploy is configured around your machines, your tooling, and your real production challenges. The result? You go live faster, program with confidence, and machine without fear of costly crashes or rework.

One of the first things our customers notice is how much faster CNC programming becomes. GibbsCAM’s intuitive interface and powerful automation allow programmers to go from CAD model to machine-ready G-code in a fraction of the time compared to many other CAM systems. This means:

- Shorter programming cycles

- Faster job turnaround

- Higher spindle utilization

- More jobs completed per shift

That is why manufacturers evaluating the best CAM software for CNC machining consistently choose GibbsCAM.

Equally important is safety. GibbsCAM is engineered to produce collision-free, highly reliable toolpaths, even for complex 5-axis and mill-turn machines. When combined with SIMTEK’s expert post processor configuration, your CNC machines receive accurate, machine-ready G-code that runs exactly as intended. Tools last longer. Scrap goes down. Confidence goes up.

What truly makes SIMTEK different is what happens after installation. As your trusted GibbsCAM partner, we provide continuous training, technical support, and process optimization. Whether you’re programming 3-axis milling, 5-axis aerospace parts, or mill-turn components, our CAM experts are always there to help you go faster, safer, and smarter.

We also take a consultative approach to GibbsCAM pricing and licensing. We design your solution around what you actually machine — not a generic bundle — ensuring you get maximum capability without paying for features you don’t need.

When manufacturers choose GibbsCAM at SIMTEK, they’re not just buying CAM software. They’re investing in a complete CNC performance system designed to drive productivity, quality, and profitability for years to come.

👉 Request a Demo and experience why GibbsCAM + SIMTEK is the smarter way to run CNC machining.

Frequently Asked Questions (FAQs)

1. Is GibbsCAM the best CAM software for CNC machining?

GibbsCAM is widely regarded as one of the best CAM software solutions for CNC machining because it combines powerful toolpath generation, machine-specific post processing, and real-world manufacturing intelligence.

2. What machines does GibbsCAM support?

GibbsCAM supports 3-axis, 4-axis, 5-axis CNC mills, lathes, mill-turn machines, Swiss machines, and multi-tasking CNC systems.

3. Why should I buy GibbsCAM through SIMTEK?

As an authorized GibbsCAM partner, SIMTEK provides professional implementation, training, post processors, and ongoing technical support—ensuring you get maximum value from your investment.

4. How does GibbsCAM pricing work?

GibbsCAM pricing is based on the modules and CNC capabilities you need. SIMTEK provides tailored pricing based on your machines, axes, and production requirements.

5. Can I request a demo before buying?

Yes. SIMTEK offers personalized GibbsCAM demos so you can see how it works on your actual parts and machines.