This is a short blog about the benefits of using SOLIDWORKS interference detection. this is very powerful tool when creating with moving parts and components in assemblies,

We would be analyzing component interferences found within the assembly interference,

Detection analyzes geometry and identifies overlapping components within a basic

Assembly.

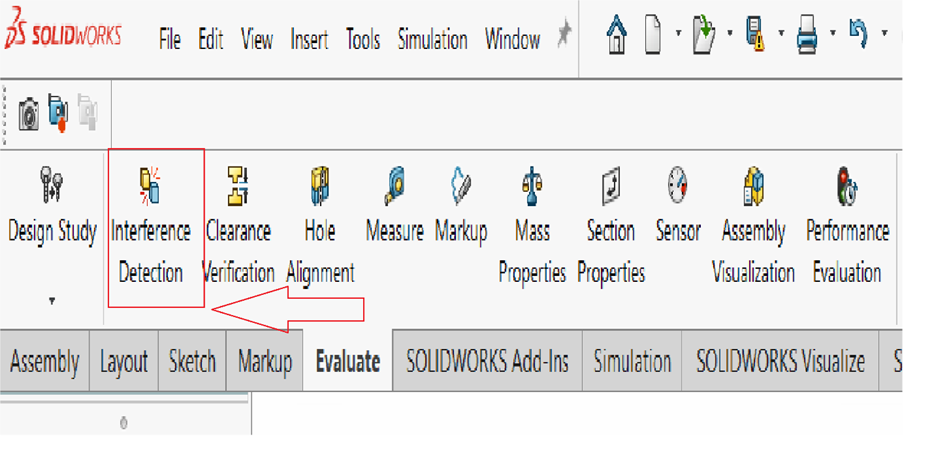

So, having a tool that can do this job is greatly beneficial interference detection is found within “Evaluate tab”

click Tools > Evaluate > Interference Detection

Interference deduction tool tab

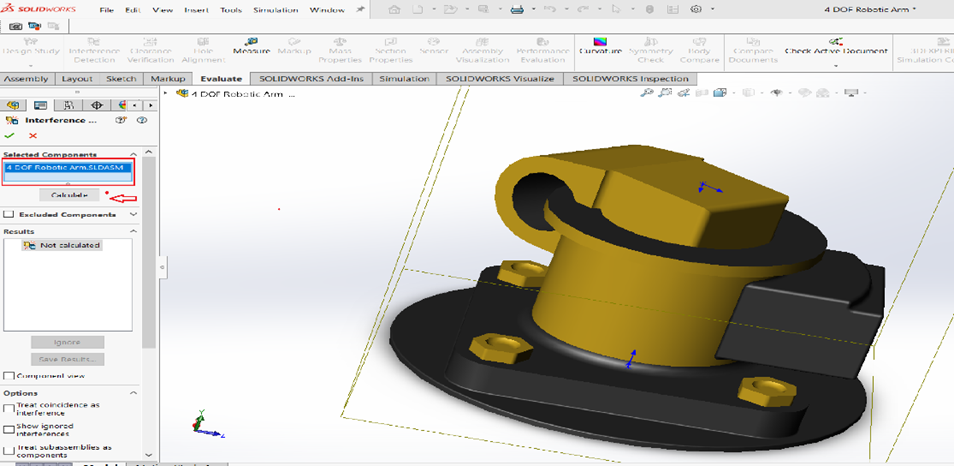

It is usually easy to see interferences but sometimes it can be difficult to determine, By default, the selected component will be assembly can delete it by right-clicking on the name of the assembly and selecting Delete, then click on the desired area of Graphics window to select new parts.

In this situation, the components have been overlapped

Overlapped component

How we can solve this kind of problem??

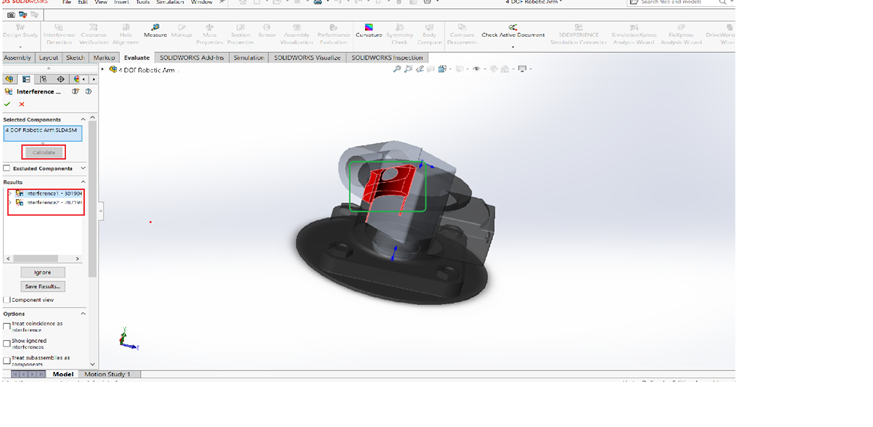

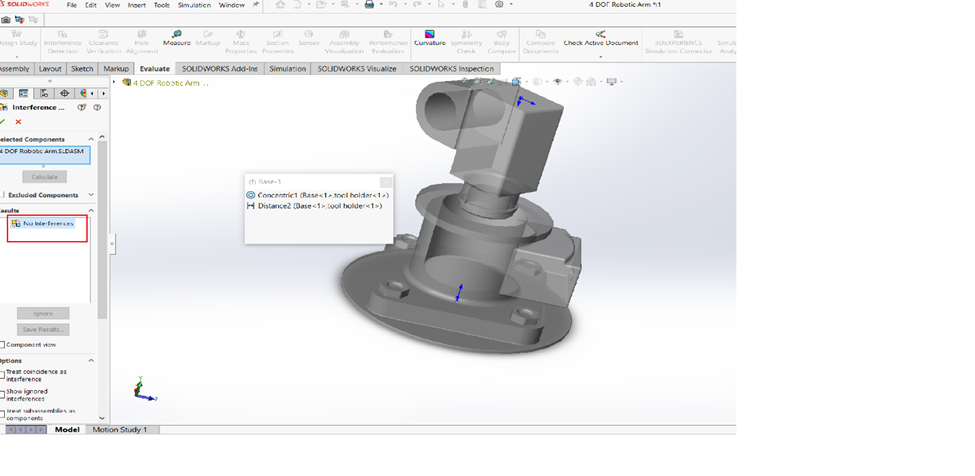

We will have the option to calculate interferences within the entire assembly or specify components and, calculate the entire component we can see that the two interferences,

The interference detection makes both components interfering transparent and Highlights the overlapping volumes make it easy to see since I made this assembly

Highlighted component

We know that there is a distance between the two interferences

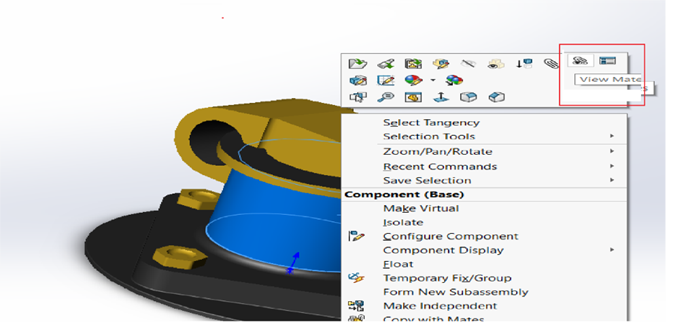

Interfering Components that we need to address even if I did not know this using the view

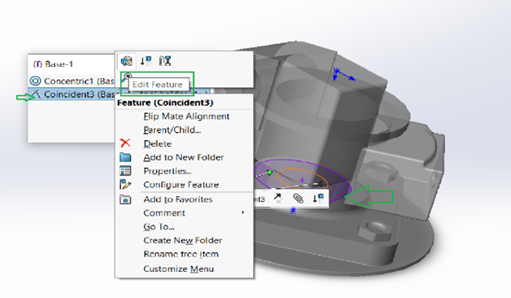

mates Tool can be a quick way to list all the mates associated with that component

View Mates option

Edit coincidence mate

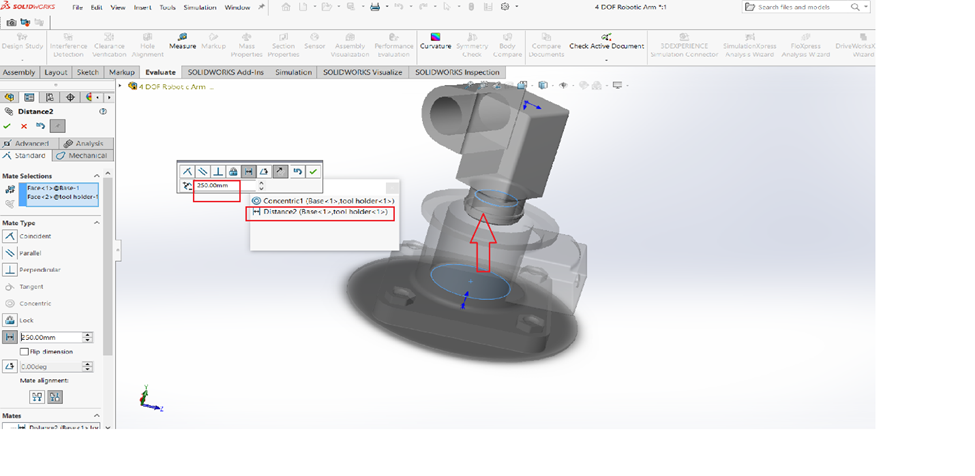

will increase the dimension around check the interference, again as you can see there Are no longer any interference this joint will be able to rotate.

Edit distance mate

We easily changed the distance, resolving the overlapping issues.

Results Section

Interference deduction was great for static interferences when it comes to dynamic

Collisions we need to use a different tool the move component command contains a

Collision detection feature will check collisions between all components, thus

interference detection can be useful to ensure that the component has the desired level of

motion.

You have noted very interesting points! ps nice internet site.Blog money