REVERSE ENGINEERING SERVICES

Reverse Engineering Services

Reverse engineering services provide businesses with the ability to analyze and reconstruct existing products, thus enabling them to understand design intricacies and improve upon them. Furthermore, SIMTEK, a leading Best authorised SOLIDWORKS reseller in Chennai, Coimbatore, Kolhapur & the rest of Tamilnadu, and India, brings inspiring capabilities to reverse engineering. In the highly competitive global marketplace, manufacturers are constantly looking for ways to shorten the time to market a new product. As a result, more and more manufacturers are opting for reverse engineering services because:

![]() The original manufacturer of a product no longer produces a product.

The original manufacturer of a product no longer produces a product.

![]() There is inadequate documentation of the original design.

There is inadequate documentation of the original design.

![]() The original manufacturer no longer exists, but a customer needs the product.

The original manufacturer no longer exists, but a customer needs the product.

![]() The original design document was lost or never existed.

The original design document was lost or never existed.

![]() Some bad features of a product need to be designed out.

Some bad features of a product need to be designed out.

![]() New avenues need to be explored to improve product performance and functionality.

New avenues need to be explored to improve product performance and functionality.

We work in detail with customers and thoroughly understand their complete needs. Furthermore, all products and solutions are meticulously simulated before prototyping, thus ensuring the highest chances of success. Consequently, we support all aspects of the project, including but not limited to initial analysis, design, testing, simulations, optimization, design analysis, redesigning, and manufacturing. In addition, our comprehensive approach guarantees seamless integration and outstanding results.

Have any additional questions? Contact us and fly on winds of change.

Our Comprehensive Reverse Engineering Services

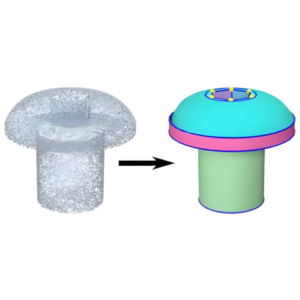

3D Scanning and Digitization

We employ state-of-the-art 3D scanning technologies to capture precise geometric data of physical objects. Specifically, we use:

- High-resolution laser scanning

- Structured light scanning

- Photogrammetry for large objects

- CT scanning for internal geometries

These technologies allow us to ensure accuracy and efficiency in our data capture process.

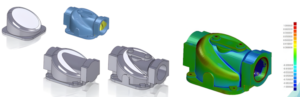

CAD Reconstruction

Our skilled engineers transform scan data into accurate, editable 3D CAD models. Specifically, we offer:

- Surface modeling for complex shapes

- Solid modeling for mechanical parts

- Parametric modeling for design intent capture

- Assembly modeling for multi-component products

Additionally, these services ensure precision and flexibility, enabling high-quality and efficient design workflows.

Dimensional Analysis

We provide detailed dimensional analysis to ensure accuracy and compliance:

- GD&T (Geometric Dimensioning and Tolerancing) analysis

- Comparison to original design specifications

- Deviation analysis and reporting

Material Analysis

Our material analysis services help identify and characterize materials:

- Composition analysis using spectroscopy

- Mechanical property testing

- Microstructure analysis

Functional Analysis

We delve deep into how products work, providing:

- Kinematic and mechanism analysis

- Performance evaluation and benchmarking

- Failure analysis and root cause identification

Design Optimization

Based on our analysis, we offer suggestions for design improvements:

- Weight reduction strategies

- Performance enhancement recommendations

- Manufacturing process optimization

Industry Applications

Our reverse engineering services cater to a wide range of industries. Specifically:

- Automotive: This includes legacy part reproduction and competitor analysis.

- Aerospace: We specialize in obsolete component replication and aircraft maintenance.

- Manufacturing: Our services cover tooling and fixture design, as well as process improvement.

- Consumer Products: We offer product benchmarking and design evolution.

- Medical Devices: This includes custom implant design and device improvement.

- Heritage Preservation: We focus on historical artifact digitization and replication.

These diverse applications highlight our comprehensive capabilities and dedication to meeting industry-specific needs.

FAQs

What types of objects can you reverse engineer?

“We can reverse engineer a wide range of objects, from small precision components to large industrial machinery. Moreover, our diverse scanning technologies allow us to capture data from various materials and sizes, ensuring comprehensive and precise results.

How accurate are your reverse engineered models?

Our models typically achieve accuracies within 0.025mm to 0.1mm, depending on the object’s size and complexity. Consequently, we always strive for the highest possible accuracy and validate our results against the original object to ensure precision and reliability.

Can you reverse engineer internal components?

Yes, we use CT scanning technology to capture internal geometries without destructive testing. Moreover, this is particularly useful for complex assemblies, especially when non-invasive analysis is required.

How do you handle intellectual property concerns in reverse engineering?

We strictly adhere to ethical reverse engineering practices and respect intellectual property rights. Furthermore, we work within legal frameworks and can sign NDAs to protect your interests. Additionally, our services focus on understanding and improving designs, rather than infringing on patents.

Can you help with obsolete or out-of-production parts?

“Absolutely! One of the key applications of our reverse engineering services is recreating obsolete parts for which no original documentation exists. Moreover, we can help you bring these parts back into production with modern manufacturing methods, thereby ensuring their functionality and reliability. Additionally, our expertise guarantees that these recreated parts meet contemporary standards and specifications.