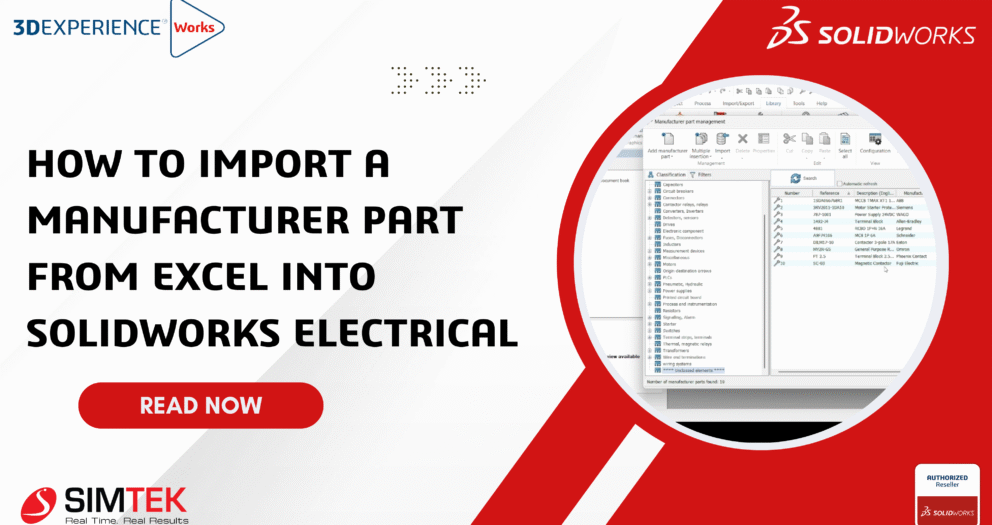

How to Import a Manufacturer Part from Excel into SolidWorks Electrical

Why Import from Excel?

• Manual maintenance of manufacturer parts can be tedious.

• With Excel, dozens (or even hundreds) of parts can be imported in one go.

• Repetitive data entry is eliminated.

• Consistency across projects and teams is maintained.

• A custom library tailored to your workflow can be built easily.

Step 1: Excel File Preparation

The Excel file must be prepared in the correct format.

SolidWorks Electrical expects specific columns. The following format should be used:

| Reference | Manufacturer | Description | Part Type | Symbol Name | Classification |

|---|---|---|---|---|---|

| 123-ABC | Schneider Electric | Contactor 24VDC | Contactor | SYM_CONTACT | Power Components > Contactor |

| 456-DEF | Siemens | Circuit Breaker 10A | Breaker | SYM_BREAK | Power Components > Breaker |

Step 2: SolidWorks Electrical Launch

• SolidWorks Electrical should be launched.

• A project can be opened, or work can be done from the library tab.

• The Manufacturer Parts Manager will be accessed next.

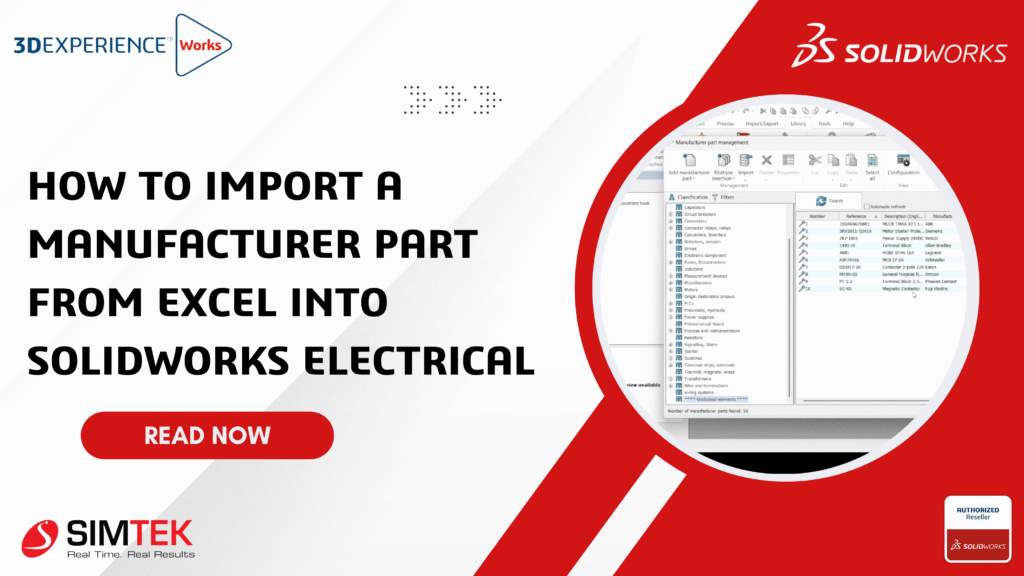

Step 3: Manufacturer Parts Manager Navigation

• The library tab should be clicked.

• "Manufacturer parts manager" should be selected.

• Within the manager, the Import > Manufacturer parts option should be clicked.

• Excel should be chosen as the file type.

• The Import Wizard will be launched automatically.

Step 4: Field Mapping

After the Excel file is loaded, column mapping will be requested by SolidWorks Electrical.

Ensure that fields such as:

• Reference

• Manufacturer

• Description

• Part Type

are mapped to their correct database fields.

Step 5: Import Completion

• Once mapping is finished, "Next" should be clicked to review the data.

• "Finish" should then be clicked.

• The Excel data will be processed by SolidWorks Electrical.

• A confirmation message will be displayed if the parts have been added successfully.

Step 6: Part Verification

• The Manufacturer Parts Manager should be revisited.

• Imported part numbers can be searched.

• They should appear in the list, with all relevant data.

Now, parts can:

• Be linked to symbols

• Be assigned to circuits

• Be used in schematics immediately

Benefits:

Time Savings

• Hours are saved through bulk imports.

• Library setups for new projects or migrations are accelerated.

Reduced Errors

• Errors are minimized through direct import from validated Excel sheets.

• Part numbers, descriptions, and manufacturers are kept consistent across projects.