3DEXPERIENCE ENOVIA

Data Management Applications Powered by ENOVIA

3DEXPERIENCE ENOVIA – SCALABLE DATA MANAGEMENT SOLUTION

As you expand, data management becomes a critical component of operations. Further, for any project to succeed, whether big or small, all components and moving parts in the project need to be tracked and managed correctly and effectively. The 3DEXPERIENCE ENOVIA oftware comes with a host of tools and features for all project types and sizes, thereby delivering total value across the design and product lifecycle.

CLOUD-BASED SOLUTION

The software is cloud-based and thus, there is no challenge in access, working, or function. With a secure solution, the need for the use of VPN and other solutions are eliminated.

ENOVIA FEATURES

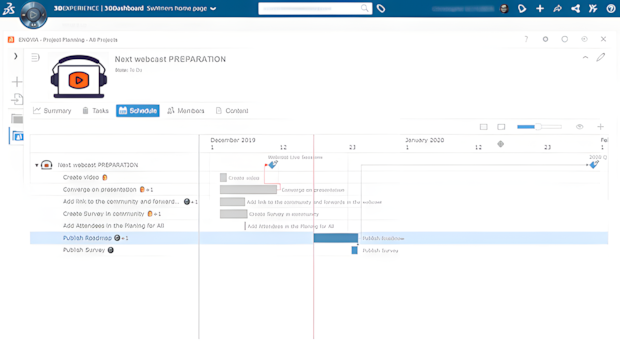

NATIVE TASK AND PROJECT MANGEMENT

A multi-functional tool means that you are able to use the system per your organization’s needs and scale up as you grow.

SEAMLESS COLLABORATION ON DESIGN

A cloud-based solution means that seamless collaboration is facilitated. The intuitive UI is designed to deliver the best UX and any information can be conveyed easily across the entire ecosystem of stakeholders.

PRODUCT LIFCYCLE AND CHANGE ACTIONS

With strong data management and version control, any revision can be tracked and the appropriate version released. With a one-stop solution, there is no chance of a miss of anything important.

Integrated directly into SOLIDWORKS

Seamless integration with SOLIDWORKS means that users are able to access all functionalities of SOLIDWORKS and thus gain a holistic and advantageous solution across the entire life cycle management of the design, product or project.

FREQUENTLY ASKED QUESTIONS

Are these tools all cloud-based?

Is this ENOVIA?

ENOVIA powers the 3DEXPERIENCE platform’s data storage and collaborative capabilities. This preconfigured version of ENOVIA is referred to as ENOVIAworks.

Where do my documents get stored while working in SOLIDWORKS?

Why is SIMTEK considered the best SOLIDWORKS reseller in Chennai?

3DEXPERIENCE AND SOLIDWORKS

SOLIDWORKS |

ENOVIAWORKS Roles |

| FEATURES | PDM PROFESSIONAL | MANAGE | COLLABORATIVE INDUSTRY INNOVATOR | COLLABORATIVE DESIGNER | PROJECT PLANNER | PRODUCT RELEASE ENGINEER | 3D PRODUCT ARCHITECT |

| Cloud Deployment | |||||||

| On-Premises Deployment | |||||||

| Desktop Installation | |||||||

| Web Browser Access | |||||||

| Floating Licensing Model | |||||||

| Named User Licensing Model | |||||||

| Automated Neutral File Creation | |||||||

| Document Workflows | |||||||

| Document Version Tracking | |||||||

| Document Revision Tracking | |||||||

| CAD Reference Management | |||||||

| Engineering Change Management | |||||||

| Project Management | |||||||

| Bills of Material Management | |||||||

| Lifecycle Management | |||||||

| Top-Down Design | |||||||

| Task Assignment | |||||||

| Customizable Dashboard | |||||||

| Customizable Reports |