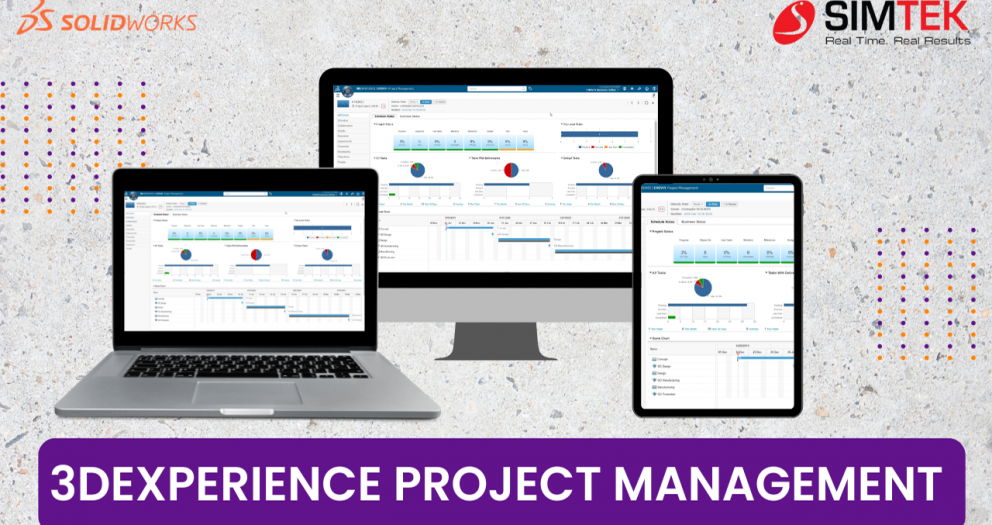

3DEXPERIENCE Project Management (FAQ)

SolidWorks 3DEXPERIENCE Project Planner empowers teams to streamline project execution through a web-based solution. This guide explores its functionalities, equipping you to harness its potential for collaborative project management.

1. what is project planner?

SolidWorks 3DEXPERIENCE Project Planner simplifies project planning by offering a browser-based solution. Teams can define, share, and complete tasks and deliverables through continuous project planning and execution. This collaborative and secure environment, powered by the 3DEXPERIENCE platform, keeps teams on track and within budget, ultimately accelerating time to market.

2. Who needs a project planner?

3DEXPERIENCE Project Planner empowers teams and organizations to manage complex engineering and product development projects. It proves valuable for various professionals, including:

Engineers and Designers: Plan and manage the development of 3D models, CAD designs, and other engineering-related tasks.

Product Managers: Plan and track new product development, including defining project timelines, assigning tasks, and monitoring progress.

Project Managers: Oversee and coordinate various project aspects, ensuring adherence to schedules and budgets.

Manufacturing and Production Teams: Align the production process with the product design and development schedule.

Collaborative Teams: Facilitate collaboration among team members, including cross-functional teams, suppliers, and partners.

Large Organizations: Manage complex projects involving multiple teams and departments with a unified platform.

3DEXPERIENCE Project Planner is ideal for anyone working on projects involving 3D modeling, CAD design, and engineering, especially when collaboration and task management are crucial.

3. The usage of a project planner?

SolidWorks 3DEXPERIENCE Project Planner offers a range of functionalities to streamline project management:

Project Planning: You can create and define projects within the software,

Task Management: Create and define projects within the software.

Resource Allocation: Create tasks and sub-tasks, assign them to team members.

Gantt Charts:Allocate resources like team members, equipment, and materials to tasks or projects for efficient utilization.

Collaboration: Utilize Gantt charts to visualize project timelines, dependencies, and critical paths.

Document Management: Store and manage project-related documents, CAD files, designs, and other resources within the system for easy access and version control.

Project Tracking: Monitor the progress of your projects and tasks in real-time. Real-time tracking lets you identify tasks on schedule and those at risk of delay, allowing for swift corrective actions.

Risk Management: Proactively identify potential risks and develop mitigation strategies.

Reporting and Analytics: Generate reports to assess project performance, resource allocation, and other key metrics.

Integration: Integrate with other SolidWorks software and tools for a holistic product design and engineering process.

4. Who needs a project planner?

SolidWorks 3DEXPERIENCE Project Planner significantly enhances productivity for teams involved in engineering, design, and product development. Here's how:

- Centralized Information: A central platform stores project information, tasks, documents, and communication, eliminating scattered information and saving time.

- Streamlined Task Management: Break down projects into tasks, assign responsibilities, and set deadlines for improved efficiency and accountability.

- Real-Time Collaboration: Real-time communication and data sharing among team members and external partners lead to faster decision-making and problem-solving.

- Visual Project Planning: Understand project structure and dependencies with Gantt charts and visual timelines, enabling efficient resource allocation and work planning.

- Resource Optimization: Allocate resources effectively to avoid overloading individuals or underutilizing resources, leading to better resource management and improved productivity.

- Reduced Errors: Version control and central document management minimize errors and rework. Teams can access the latest design documents and CAD files, improving quality and reducing correction time.

- Proactive Project Monitoring: Real-time project tracking allows for early identification of potential delays or issues. This proactive approach enables teams to take corrective actions swiftly, preventing small problems from becoming major setbacks.

- Data-Driven Improvement: By analyzing project performance, resource utilization, and other key metrics data, you can identify bottlenecks and areas for improvement in future projects.

- Integration Benefits: Integration with other SolidWorks tools and third-party software streamlines workflows and reduces manual data transfer, enhancing productivity by eliminating redundant tasks.

- Risk Mitigation: Identify and manage project risks to avoid costly delays and disruptions.

In summary, SolidWorks 3DEXPERIENCE Project Planner improves productivity by streamlining project management processes, enhancing communication and collaboration, reducing errors, and providing insights into project performance. It helps teams work more efficiently and effectively, ultimately leading to faster project completion, cost savings, and higher-quality outcomes.

5.Is it possible for me to make manual edits to the project? Or Certainly, here's the rewritten version?

Yes, you can make manual edits within your SolidWorks 3DEXPERIENCE Project Planner. The software typically provides user-friendly interfaces for creating, modifying, and updating project details, tasks, timelines, and resources. You can edit project plans, adjust task assignments, update deadlines, and make other changes as needed to keep your project information accurate and up-to-date. These manual edits are an essential part of actively managing your projects and adapting to changing circumstances.

6. it is only for internal purposes or it has any external community can use it?

SolidWorks 3DEXPERIENCE Project Planner empowers you to manage internal projects and collaborate with external partners or communities. The software facilitates communication and collaboration among all project stakeholders, including internal team members, external collaborators, suppliers, customers, and partners.. This flexibility allows for a broader and more inclusive approach to project planning and management, enhancing transparency and coordination across the entire project ecosystem.

7. Is it only for any specific project or we can do anything?

SolidWorks 3DEXPERIENCE Project Planner targets engineering, design, and product development projects. It specifically tailors its features to support tasks and activities commonly found in these fields. While it is highly versatile within this context, it may not be the most suitable tool for managing projects in unrelated fields, such as construction or event planning.

In summary, SolidWorks 3DEXPERIENCE Project Planner is most effective when used for projects in the engineering, design, and product development domains. It may not be as well-suited for managing projects outside of these areas.

Task Scheduler:

Focus: Task Scheduler is primarily focused on managing and automating individual tasks or processes within a project.

Scope: It deals with the execution and scheduling of specific tasks, often related to routine or repetitive activities

.

Automation: Task Scheduler is commonly used to automate tasks like backups, data imports, script executions, and system maintenance. It's more about automating technical or operational processes.

Granularity: It can manage tasks at a granular level, often focusing on individual actions rather than the overall project.

Project Planner:

Focus: Project Planner is designed for comprehensive project management, from planning and resource allocation to execution and monitoring of the entire project.

Scope: It deals with the entire project lifecycle, including defining project objectives, creating task dependencies, assigning resources, tracking progress, and generating reports.

Project Management: Project Planner is a tool for managing projects of varying complexities, such as product development, construction, event planning, and more. It encompasses all aspects of project management.

Granularity: Project Planner offers a broader perspective and can handle tasks at various levels, from high-level project phases down to detailed task management.

Task Scheduler excels at automating and managing specific, recurring tasks or processes, often technical or operational in nature. In contrast, Project Planner tackles comprehensive project management. It handles the entire project lifecycle and is well-suited for complex projects with diverse tasks and dependencies. The choice between them depends on your specific needs and the scale of the project you are managing.